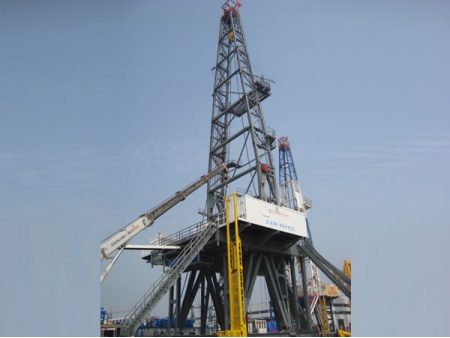

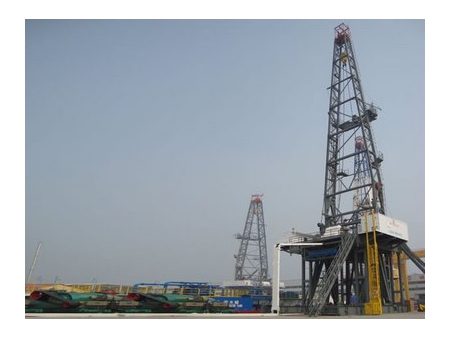

ZJ70 Skid-Mounted Drilling Rigs

Request a Quote

Application

The ZJ70 skid-mounted drilling rig is suitable for drilling wells with the depth limited within 7000m. Customers can use this drilling equipment in different environments like shallow sea areas, beaches, desert and districts with low temperature according to their practical needs.

Features

- The drawworks and mud pump of our skid-mounted drilling rig adopt hydraulic and compound chain transmissions. 3 sets of A12V190PZL-3 diesel engines and their hydraulic couple reduction gearbox together form the power units. The power unit is assembled on the pedestal of the backstage drill floor. Parallel compounded by multi-axis integral chain boxes, the power unit will drive two sets of 1600hp mud pumps respectively by two cardan shafts. The compound boxes and the input end of the drawworks are butted by butt joint chain box. The drawworks is assembled on the pedestal for drawworks in a low position.

- A hydraulic disk brake is installed on the drawworks. The drawworks has the functions of automatic bit feeding with constant pressure, metical and electric collision protection, and emergency operation.

- The rotary table is powered by a 400V AC variable frequency motor whose rated power is 600kW and driven by a double-gear gearbox. Stepless speed regulation is available to the rotary table. Thus our skid-mounted drilling rig can meet the drilling requirements of large torque and high speed.

- The derrick is in K-shape. With the stand bar assembled on the pedestal under the substructure of the skid-mounted drilling rig, the derrick can keep steady in operation and can be lifted with power provided by the drawworks.

- The spinning-lifting drill floor is 10.5m in height. On the drill floor there are the rotary table with its driving devices, hydraulic cathead and the pneumatic winch. The key components of the drill floor can be assembled in a low position and then hoisted integrally with power provided by drawworks.

- Our skid-mounted rig is equipped with a VFD system and MCC system. The VFD system and the MCC system are respectively used to control the AC variable frequency motor for rotary table and the variable frequency motor for automatic bit feeding.

| Nominal drilling depth | 4500-7000m (drill rod:114mm) | |

| 4000-6000m (drill rod:127mm) | ||

| Maximum hook load | 4500kN | |

| Hoisting rope system | 6×7; Successively twined | |

| Rated power ofdrawworks | 1470kW (2000hp) | |

| Diameter of drilling wire rope | Φ38mm | |

| Opening diameter of rotary table | 950mm (37 1/2") | |

| Gear number of rotary table | One gear | |

| Drilling pump quantity and power | 2×1600hp | |

| Gear number ofdrawworks | 6 forward 2 reverse | |

| Substructure height and clearance height under rotary table beam | 9m; 7.6m | 10.5m; 9m |

| Derrick shape and effective height | K-shape; 45m | |

| Transmission mode | Hydraulicand compound chain transmission AC-VFD-AC | |

| Main diesel engine quantity and power | 4×810kW | |

| Auxiliary generator set quantity and power | 3×400kW | |

| Maximum weight of drill string | 2200kN | |

| High pressure mud manifold | Φ102mm (drift diameter)×35MPa | |

| Effective volume of solid control system | ≥320m3 | |