Electromagnetic Separator (Dry Type)

Electromagnet Separation Equipment

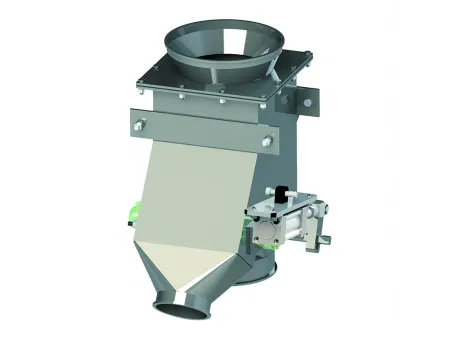

Magnetic powder separator for removing fine ferromagnetic particles from dry powdered materials

The dry-type electromagnetic separator efficiently removes ultra-fine ferromagnetic impurities at the micron and sub-micron level from dry powders. It is widely used in the lithium battery industry, including applications in lithium salts, cathode materials, and anode materials. Additionally, it plays a crucial role in industries such as food processing, pharmaceuticals, ceramics, plastics, and fine chemicals.

The dry-type electromagnetic separator is designed for the precise removal of ferromagnetic impurities from dry powders and granular materials. Using electromagnetic effects, it controls the presence or absence of magnetism by switching the power on or off. When the system is powered on, the electromagnetic coil generates a magnetic field in the core medium, attracting and capturing ferromagnetic particles from the raw material, ensuring a cleaner final product.

Once the power is turned off, the medium demagnetizes, allowing the collected impurities to be released and removed through gravity or assisted vibration. This technology is widely used in industries that require high-purity materials, such as lithium battery production, food processing, pharmaceuticals, ceramics, and fine chemicals. Its automated operation and ability to handle fine particles make it an essential tool for improving product quality and process efficiency.

- Lithium Battery Industry

Ternary lithium, lithium carbonate, lithium iron phosphate, graphite, hard carbon, conductive agents, sodium battery materials. - Chemical Industry

PVDF, coating additives, electronic-grade materials.

| Nominal diameter | DN250,DN300 |

| Ambient temperature | Equipment:-20 to 40℃ Control panel:0 to 35℃ |

| Voltage | 3-phase 5-wire,AC380V,50Hz |

| Air pressure | 0.4-0.7MPa |

| Cooling water temperature | DN250 ≤25℃ DN300 ≤15℃ |

| Excitation power | 8.4-9.5kW |

| Max. surface magnetic field strength of screen | Approx.14000GS |

| Air core magnetic field | 3500GS (±200) |

| Operation mode | Continuous operation |

| Screen | Standard screen:interval 5mm,17pcs (DN250),18pcs (DN300) (interval options of 7mm,10mm and 20mm are available as per customer request) |

| Inlet | Quick soft connection Ø326.5-380mm |

| Processing capacity | 500-800kg/h |

| Cooling oil | Approx. 150-195L |

| Total power | Approx. 10-11kW |

| Weight | Approx. 2500-2800kg |

| Nominal diameter | DN250,DN300 |

| Ambient temperature | Equipment:-20 to 40℃ Control panel:0 to 35℃ |

| Voltage | 3-phase 5-wire,AC380V,50Hz |

| Air pressure | 0.4-0.7MPa |

| Cooling water temperature | No higher than 15℃ |

| Excitation power | 15.5-18kW |

| Max. surface magnetic field strength of screen | Approx. 20000GS |

| Air core magnetic field | 6000GS (±200) |

| Operation mode | Continuous operation |

| Screen | Standard screen:interval 5mm,18pcs (interval options of 7mm,10mm and 20mm are available as per customer request) |

| Inlet | Quick soft connection Ø326.5-380mm |

| Processing capacity | 500-800kg/h |

| Cooling oil | Approx. 170-195L |

| Total power | Approx. 17-19.6kW |

| Weight | Approx. 3800-4200kg |

- The excitation coil is designed using finite element analysis (FEA) to optimize the magnetic field distribution. This ensures the highest possible magnetic strength while maintaining a large effective flux volume. The uniform magnetic field reduces intensity loss over the filtration path, improving the ability to capture ferromagnetic impurities and enhancing filtration precision.

- The excitation coil is manufactured following high-voltage transformer standards, providing high insulation and durability. With an H-class insulation rating, the coil is resistant to electrical stress and has a lifespan of at least 10 years, ensuring long-term stability and reliable performance.

- The cooling system is developed using flow field analysis to enhance heat dissipation and maintain coil stability. The coil and cooling oil undergo efficient heat exchange, while the forced circulation cooling system, supported by an oil circulation pump and heat exchanger, ensures consistent cooling. The external cooling oil circuit is made of stainless steel, keeping the system clean and requiring minimal maintenance.

- A high-frequency vibration system improves material flow, especially for powders with poor fluidity or materials with weak magnetic properties. The vibration mechanism enhances impurity discharge by preventing blockages and ensuring complete removal of trapped particles. A flexible damper between the vibration system and the machine body absorbs vibrations, minimizing noise and mechanical stress on the equipment.

- The machine is designed with clearly labeled interface connections, making installation, operation, and maintenance straightforward. The structure follows ergonomic principles, ensuring ease of use while incorporating safety features for reliable operation.

- The intelligent control system integrates PID-based closed-loop voltage regulation and constant magnetic field control. These two advanced control methods use negative feedback to stabilize the output, preventing fluctuations caused by changes in grid voltage. The constant magnetic field control, a unique feature in this type of equipment, prevents a decrease in magnetic strength due to coil temperature rise, maintaining consistent performance.

- A dedicated PLC control cabinet with IP54 protection allows for fully automatic ferrous metals removal and cleaning cycles. The built-in touchscreen interface provides easy access to system settings, allowing operators to adjust cleaning phase durations according to different raw materials and processing conditions.

- A remote communication interface enables seamless integration with centralized control systems, allowing real-time monitoring and remote operation. This feature ensures efficient system management and enhances overall process automation.