Vector Inverter (General Purpose), ES450 Series

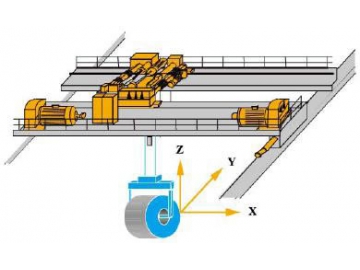

Our general purpose vector inverter provides high vector control in machining tools, ceramic machinery, hoisting cranes, air compressors, and other tools in petroleum and chemical, textile, and engineering industries. With high torque and failure-free operation, the inverter motor is efficient and flexible in its application. The inverter features overload and current limiting safety features.

Advantages:

1. Advanced speed-sensor vector control which reduces the sensitivity to motor parameters for increased control.

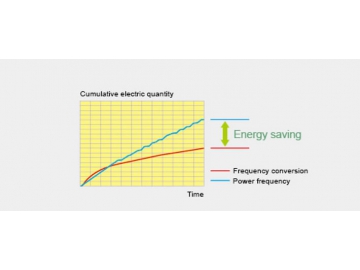

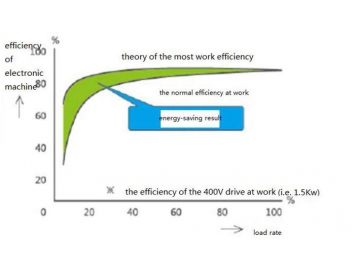

2. Energy saving mode which monitors the actual load size and automatically adjusts the motor voltage and current accordingly.

3. High torque capabilities using PID control technology which monitors motor speed changes and holds loads constant.

4. Flexible input/output terminals with more than 60 functions and 15 optional functions for analog output for calibrating curve and precision.

5. Current limiting function which enables the frequency converter to operate within the limited current values of the hardware before reaching overcurrent and possible damage.

6. Motor overheating protection which switches the frequency converter into downtime when the temperature rises.

7. Protects mechanical torque limit

8. Droop control which adjusts the rotating speeds when multiple motors drive the same load so the machine is balanced.

9. Flexible multi-stage V/F control which adapts efficiency with different loads.

10. Overvoltage protection

11. Compact structure and easy to install fan.

12. The Infineon IGBT module ensures reliability and a wide voltage range makes the inverter adaptable to power grid fluctuation. TUV certified.

| ITEM | SPECIFICATIONS | |

| Main input | Rated voltage and frequency | Single-phase 200V class: 200V-240V,50Hz/60Hz |

| 3-phase 400V class: 380V-480V , 50Hz/60Hz | ||

| Allowable value of change | Voltage: 380V-15% ~ 480V 10%; Frequency: 15% | |

| Main output | Output voltage | Maximum output voltage equals to input voltage |

| Output frequency | 0.5 Hz to 400 Hz | |

| Overload capacity | 150% of rated output current for 60s, 200% of rated output current for 2s | |

| Control performance | Modulation mode | 3-phase PWM, 2-phase PWM |

| Control mode | V/f control for constant torque, V/f control for quadratic load, vector control without PG (open loop control), energy-saving | |

| Setting method of run command | Outer terminal, keyboard panel or serial communication | |

| Setting method of speed command | Analog setting, keyboard, serial communication, UP/DOWN speed setting from external terminal | |

| Speed setting resolution | Keyboard: 0.1 Hz | |

| Analog setting: 0.05/50Hz (10bit) | ||

| Speed control precision | V/f control:±2% | |

| Vector control without PG (open loop control): ±0.2% | ||

| Speed control range | V/f control 1:40 | |

| Vector control without PG (open loop control) 1:200 | ||

| Acceleration and deceleration time | 0-3200.0s | |

| Switching frequency | 1.5 kHz ~ 12 kHz, according to junction temperature automatically reduces the switching frequency | |

| Analog input | Number | 2 ways: AI1 、 AI2 |

| Type | DC voltage or DC current | |

| Maximum input range | AI1: 0 to 5VDC, 0 to 10VDC, 0/4 to 20mA DC receivable AI2: 0 to 10VDC or PTC probe input receivable | |

| Analog output | Number | 1 way: AO1 |

| Type | DC voltage or DC current | |

| Maximum input range | Voltage output: 0 to 10V, current output: 0/4 to 20mA | |

| Logic input | Number | 0.75kw-11kW:LI1,LI2,LI3,LI4,AI1,AI2 15kW-500kW:LI,LI2,LI3,LI4,LI5,LI6,LI7,LI8,AI1,AI2 Note: 2 virtual logic input, capable of configuring AI1 and AI2 into logic input port (positive logic or negative logic) |

| Type | Source or Sink | |

| Maximum input range | 0-24VDC | |

Shanghai STEP Electric Corporation

Shanghai YIXIN International Trade Co., Ltd.