Guide Pillar

Material

SUJ2, 1.2067, equivalent

20Cr, 20Cr4, SCr435, equivalent

Hardness

HRC58-62

Specifications

Standards: MISIMI / DIN / AISI etc.

Mounting Method: flange fixing

Service: OEM is available, and standard products are in stock

Customization is available

Tolerance: press-fit part: M5, sliding part: -0.001mm to -0.005mm, head: -0.2mm to -0.1 mm

Diameter Arrange: Φ8.0mm to Φ120mm or according to customer's demand

Polishing: can be close to Ra 0.4; the standard is R0.8

Our metal guide pillar features good quality and high precision; we adopt nitrogen treatment to improve the hardness of our guide pillar. Additionally, if required, other dimensions, lengths and Materials are available.

More products can be produced according to DANLY / DME / HASCO / TOHATSU / FIBRO / AGATHON / STRACK / PEDROTTI / RAYMOND / FUTABA / SANKYO / PROGRESSIVE / RABOURDIN, etc.

Introduction

The guide pillar is a kind of press die component used in combination to ensure precise positioning of mold's guide elements. The guide pillar's materials are generally bearing steel and hot die steel. The amount of bearing steel SUJ2 is larger, thus the guide post can have better durability and performance. The guide pillar has beautiful metallic luster. The guide pillar is generally cylindrical and has oil groove. The number of oil grooves increases according to the guide pillar's extended length, and the number of oil grooves is maximally 8.

Classification

In accordance with the different uses, the guide pillars can be divided into pillar for automotive mold guide, independent guide pillar, guide pillar for mold, guide pillar for stripper plate; according to the different directions, the guide pillars can be divided into slide guide pillar (Code SGP) and rolling guide pillar (Code SRP); conforming to different ways of installation, the guide pillars can be divided into loading type guide pillar and guide pillar press fit type.

Center Hole

The roundness guide pillar is a very important press die component. It is primarily used to punch the center hole and facilitate the cylindrical grinder to grind the diameter. When the cylindrical grinder is grinding the diameter, the center hole can withstand the rotating grinding.

Further Information

| Testing Machine | Digital height gauge, caliper, coordinate measuring machine, projection machine, roughness tester, hardness tester, etc. |

| QC | 1) Technicians do self-check in the production 2) Engineers do spot check in the production 3) QC personnel do inspection after the mass production finished 4) International salesmen with technical know-how do spot check before shipping |

| Main Markets | North America, South America, Eastern Europe, West Europe, North Europe, South Europe, South Asia |

Main Products

Punch Pins, Ball-Lock Punches, Punch Retainer

Die Button

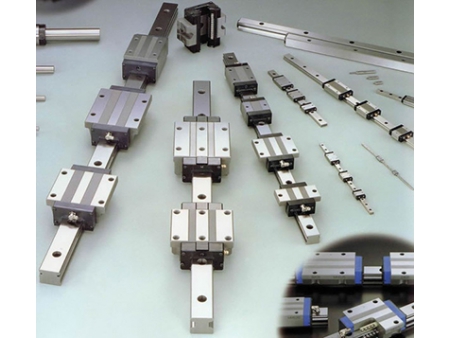

Guide Pillars, Guide bushings, Guide Post Set, Ball Cages

Ejector Pins, Ejector Seeves, Oiless Bush, Bronze Wear Plate