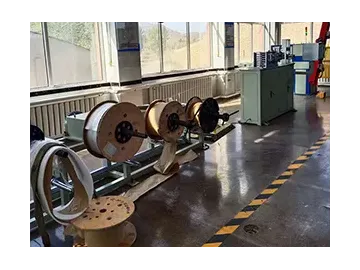

Loop Winding Machine

Request a Quote

Loop winder for the production of stator coils for motors and transformers Applications

Loop winding machine is widely used for the production of large and medium-sized motor stator coils and transformer coils.

Specifications

| Traction line length | 100-600mm |

| Conductor width | 2-12mm |

| Conductor thickness | 1-8mm |

| Coil length | 600-4500mm |

| Section width | 10-24mm |

| Winding bobbin | R20, R25, R30, R90 |

| Number of wire de-reeler | 4-8 |

| Number of parallel wire | 1-8 |

| Winding speed | 5-100r/min |

| Maximum load | 1400kg |

| Counting capacity | 999 |

| Damping torque | 10-100N.m (tension can be adjusted according to specific needs) |

Features

- Loop winding machine is controlled by human-machine interface touch screen PLC system, with both manual and automatic operation modes.

- The working pressure and stroke of loop winding machine can be adjusted within the specified range according to your needs, and the stroke can be fixed.

- The working table is pushed and pulled by a leadscrew, which is convenient for loading and unloading with accurate positioning and reliable press fitting.

- Our loop winding machine can work for a long time with good stability and high production, which is a great solution for mass production.

- Loop winder can be used for various types of motor stator coil winding with multiple payoff reels, which is suitable for both single coil winding and parallel winding of multiple coils.

- A PLC system is used for precise control, and its magnetic damper enables stepless adjustment of reel tension and rotational speed.

- The main control unit adopts programmable logic controller (PLC) from Mitsubishi of Japan; The low-voltage circuit breaker and AC contactor are products of Schneider.

- The loop winding machine is equipped with an automatic interlocking, with a floating device for automatic compaction and straightening of the copper wire, which also maintains a controlled and constant conductor tension. Production safety is taken into consideration and well designed.

Key Advantages

- A Japan Mitsubishi PLC system is adopted and the loop winder can be controlled through the control cabinet and touch screen, which has anti-mistake touch protection.

- Loop winding machine unwinds the wire with a constant tension. After the previous coil has been wound and the copper wire has been cut, the coil manufacturing machine is able to maintain the tension on the copper wire within the set tension value.

- Automatic operation of the loop winding machine can be achieved, i.e., automatic wire loading, wire counting, wire cutting, etc. The winding length can be automatically adjusted to the set length.

- The feeding process is controlled by servo motor, which can ensure the accurate feeding length.

related coil equipment

Get The Right Advice.Contact Our Team Today

Have a question or need advice? Our team has the expertise to recommend the right solution.

Tell us your question

We will be in touch with you as soon as possible.