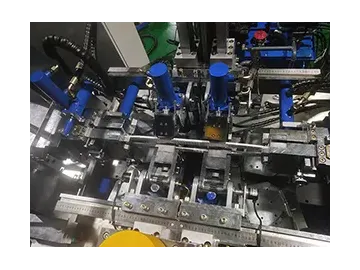

Coil Forming Machine

This coil forming machine is designed to produce motor coils by opening the loop and forming it into diamond-shaped coil. The parameters of coil forming machine can be programmed by microcomputer during the coil forming process. After manually loading the coil and press the start button, the coil processing machine can automatically control and realize the precise forming of coil evolutes. After a coil is formed, the clamp will be released automatically to enable the manual removal of finished coil, and then the equipment will be reset automatically. The diamond-shaped coils produced by this coil making machine do not have any mechanical damage, and the insulation between the turns of the coil is intact, which ensures the reliable electrical performance of the coil.

Coil forming machine runs based on the principle of synchronized and consistent movement, to ensure that the spanning distance between the two ends is consistent, and it can be accurately inserted into the motor slot.

Specifications| Overall loop length | 700-3500mm |

| Slot length | 600-3450mm |

| Slot part radius | 15-20mm |

| Coil stack width | 4-30mm |

| Coil stack height | 12-70mm |

| Coil straight side length | 230-2500mm |

| Coil length | 520-3200mm |

| Coil width | 150-1050mm |

| Lift | 0-400mm |

| Evolute angle | 0-30° |

| Angle accuracy | ±0.1° |

- Top arc forming function for accurate coil positioning

- Uniform coil shape with precise control over angles and size

- Coil forming machine is suitable for all types of stator coils. The main drive adopts servo and the clamp adopts hydraulic cylinder and regulating valve to ensure accurate positioning of each workstation. The four-arm stretching is driven by using servo motor and ball screw, thus resulting in an accurate positioning and high precision.

- The operations of coil opening and coil evolutes forming can be adjusted seperately, with a high degree of automation and simple operation.

- Coil former can work continuously to get higher production efficiency.

- A CNC servo is adopted to control the angle of coil opening, therefore providing a finished coil with higher precision.

- All data can be input directly through the touch screen, which is more convenient and quicker.

- The coil can be automatically set and centered to ensure that the coil meets the design requirements.

- Coil forming machine runs based on the principle of synchronized and consistent movement, to ensure that the spanning distance between the two ends is consistent, and it can be accurately inserted into the motor slot.

- The top arc system adopts the rotating mode to ensure the forming requirements of different arcs and specifications of the coil ends.

- All processes are automated except loading and unloading.

What are the main steps involved in manufacturing high-voltage motor coils?

What insulation techniques are typically used for high-voltage coils?

How are high-voltage motors assembled and tested?

The process includes two main stages:

- Component assembly: This includes installing the stator and rotor units.

- Final assembly and testing: Bearings are mounted, the air gap is calibrated, and a series of functional tests are conducted to verify alignment, insulation strength, and mechanical stability.