Permanent NdFeB Magnet

Permanent NdFeB Magnet

Permanent NdFeB magnet is composed of Nd,Fe,B and other few minor elements., it can be supplied in kinds of shapes such as rings,blocks and other custom made magnet. As the Neo magnet is the most powerful rare earth magnet up to now and regarded as the King of permanent magnets. Nowdays, the Neo magnet are under a very fast development and wide application, such as permanent magnet DC motors,hi-fi stero systems,magnetic separator,etc.

Generally, the permanent NdFeB magnet is used in the following industries.

Sonic equipment: earphone, microphone, loudspeaker.

Apparatus: electricity meter, voltmeter, flow-meter, tachometer.

Medical device: water magnetizer, magnetic resonance image device and therapy device.

Micro motor and special motor: voice coil motor (VCM), step motor, texture motor, geared down motor, disk motor, servo motor, and permanent-dynamic system.

Industry installation: magnetic clamp, crane, filter, coupler and switch, as well as CD-ROM, generator, petrol equipment and separator.

:()

Applications

Product Attributes

Our competitively priced product offers high resistance to demagnetization and high energy for size.

The material is corrosive, so it should be coated for long term maximum energy output.

It works well under ambient temperature. The working temperature for heat applications is not high.

Tolerance

For pressed material, tolerance on the thickness is ± 0.005, and tolerance on other dimensions is ± 2.5% or ± 0.010. Sintered metallic magnets usually have the following visual imperfections, like hairline cracks, porosity and minor chips. According to our standards, if the missing surface is below 10 %, we think the chipped edge is acceptable. Also, a crack which doesn’t extend across over 50 % of the pole surface is acceptable.

Magnetizing and Handling

The product is a very brittle material with a strong magnetic force. Hence, please handle with care and strive to avoid any personal injury or product damage. Fingers between attracting magnets can be pinched severely. When constructing rare earth magnetic assemblies, magnetizing the product after assembly is recommended.

Machining

As the neodymium magnet material is prone to chipping and cracking, it requires special machining methods. For instance, it allows abrasive grinding, but liberal amounts of coolant should be used. This is because the coolant keeps heat fracturing to a minimum and reduces the risk of fires due to oxidized grinding dust.

Coating/Plating

1. Zinc coating with relatively low resistance to corrosion

It can provide limited corrosion protection against humidity, stain, etc.

2. Zinc coating with relatively high resistance to corrosion

It is highly resistant to corrosion caused by atmosphere influences, humidity as well as chemicals.

3. Multiple coating: copper nickel

The coating allows the permanent NdFeB magnet to be safely exposed to environment possibly with dew and maintain stability in appearance and performance for a long lifetime.

4. Multiple coating: nickel tin

The coating makes the material suitable for occasions where welding or electric contact on the surface is required.

5. Epoxy coating

It protects the material against atmospheric influences, humidity and chemicals.

6. Phosphate coating

It provides the material with temporary protection during transport or short term storage

:,()

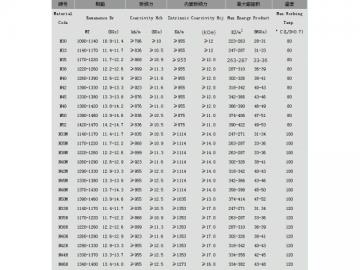

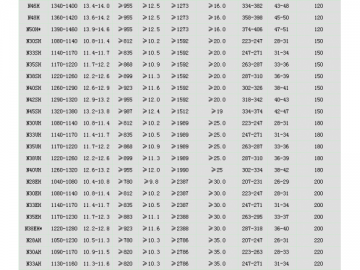

1. Material code

2. Remanence Br

3. Coercivity Hcb

4. Intrinsic coercivity Hcj

5. Max. magnetic energy product

6. Max. working temperature

Technical Data