Aluminum Nickel Cobalt Magnet (Alnico Magnet)

AluminumNickel Cobalt Magnet (Alnico Magnet)

Alnico magnetis a type of permanent magnet mainly composed of aluminum, nickel andcobalt. It also contains a small amount of copper, and sometimes titanium. Withhigh coercivity andmagnetic force, the material is extensively used in applications includingelectric motors, electric guitar pickups, microphones, sensors, loudspeakers,

Cast Alnico

This material is manufactured by pouring the molten alnico alloy into amold. After solidification, it undergoes rough grinding, heat treatment andcooling processes. The material is anisotropic when it is treated in a magneticfield. This results in the material taking on maximum magnetization and allowsa higher gauss level. When not treated in a magnetic field, the alnico isisotropic. The material can be ground to specific tolerances and magnetizedafter heat treatment and cooling.

Attributes

With size parameters ranging from 1 ounce to about 70 pounds, this alnicocan be cast into various shapes and sizes.

Sintered Alnico

This material is produced from a powdered mixture of ingredients. Themixture is pressed into a die under tons of pressure, sintered in a hydrogenatmosphere and then cooled. The material is anisotropic when cooled in thepresence of a magnetic field, otherwise, it is isotropic.

Attributes

The sintered alnico is mechanically strongest. With size parameters rangingfrom about one ounce to one cubic inch, the material can be pressed to a veryclose tolerance and requires minimal grinding.

Common Attributes between Both Cast Alnico and Sintered Alnico

These materials have goodtemperature stability, so they are suitable for high heat applications. In fact, their maximum workingtemperatures are from 975 to 1020° F.

These materials can be groundto the required size.

Unlike ceramic material, they are high residual induction and energy products.

5 and 8 are most commonly used grades of cast alnico.

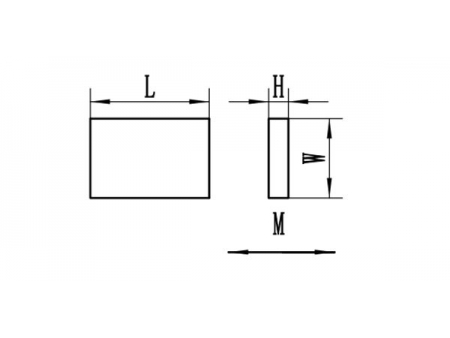

Tolerance

Our tolerances on material meet and always exceed applicable industrialstandards.

Magnetizing and Handling

Please ensure the magnetizing is carried out only after aluminum nickelcobalt magnet has been machined to the required tolerance. Being brittle, thematerial is prone to chipping or breaking when dropped on a hard surface, soplease handle it with extreme care. In addition, the improperly stored magnetmay lose power due to its low demagnetization resistance. Therefore, customershad better store magnetized alnico so that pieces are attracting each other, orwith a steel keeper.

Machining

Hard and brittle, aluminum nickel cobalt magnet materials require specialmachining methods. With experienced machinists and the proper equipment, ourcompany can well perform any alnico machining tasks.