SmCo Magnet (Samarium Cobalt Magnet)

SmCo Magnet (Samarium Cobalt Magnet)

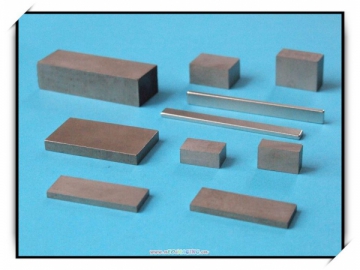

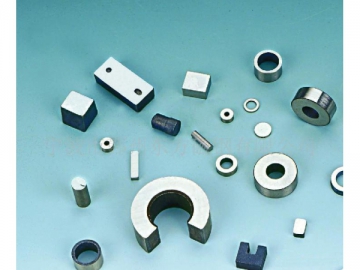

Permanent SmCo magnet is a powerful rare earth magnet, which is mainly made of samarium, cobalt and iron. Although the material provides lower magnetic force than neodymium type, it has higher temperature ratings and higher coercivity. It is available in various simple shapes for users to choose from, like ring, block and disc.

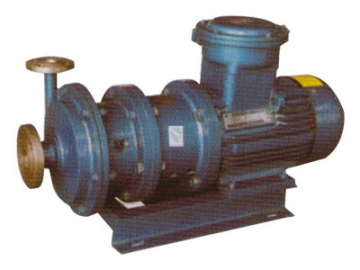

Featuring strong magnetic strength, high demagnetization resistance and good temperature stability, the samarium cobalt magnet is widely used in high-end electric motors, turbo machinery, low or high temperature resistant instruments, and equipment with changing working temperature.

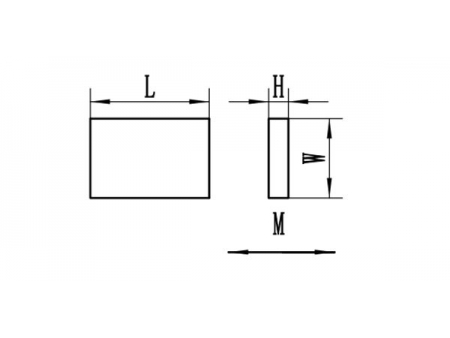

Tolerance

For pressed material, tolerance on the thickness is ± 0.005, and ± 2.5% or ± 0.010 is the tolerance on other dimensions. Hairline cracks, porosity and minor chips are some visual imperfections usually found in sintered metallic magnets. According to our standards, we think a crack which doesn’t extend across over 50 % of the pole surface is acceptable. A chipped edge is also considered acceptable if no more than 10% of the surface is missing.

Magnetizing and Handling

As the material is easily broken and magnetically strong, extreme care should be taken to avoid personal injury and product damage during handling. The material tends to chipping if allowed to “jump at” an attracting object, and attracting magnets can make fingers severely pinched. When constructing rare earth magnetic assemblies, magnetizing the product after assembly is recommended.

Machining

The ease of chipping and cracking makes conventional machining methods unsuitable for SmCo magnet material. Hence, the material requires special machining methods. For example, it can be abrasively ground with the use of liberal amounts of coolant that can not only reduce heat fracturing but also minimize the possibility of fires resulting from oxidized grinding dust.

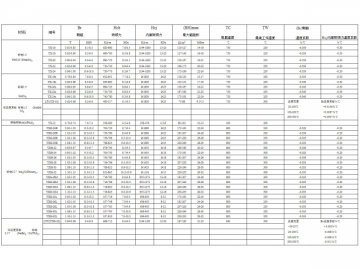

:()

1. Material

2. Code

3. Br

4. Hcb

5. Hcj

6. (BH) max.

7. TC

8. TW

9. (Br) Temperature coefficient

10. (Hcj)Temperature coefficient

11. 1:5 Smco5 (Smpr) co5

12. 1:5 Smco5

13. Smco5 low temperature coefficient

14. ce(coFecu)5

15. 2:17 Sm2 (CoFecuzr)17

16. 2:17 Low temperature coefficient (SmEr)2 (CoTM)17

17. Temperature range

18. Br%℃ Temperature coefficient of Br %℃