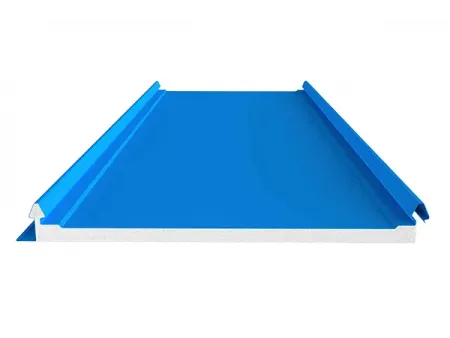

Sandwich Roof Panels (Good Cladding@)

PUR/PU insulated roof panels designed for the rail-less mounting of photovoltaic panels without drilling, meeting the requirements of thermal and acoustic insulation

- Effective width: 430mm

- Length: 1m-12m (customizable)

- Sandwich panel thickness: 20mm

- Metal sheet thickness: 0.4mm-0.7mm

- Core material: Rigid polyurethane (PUR/PU)

- Metal sheet material: Galvalume steel sheet, titanium zinc sheet, Al-Mg-Mn alloy sheet

These newly developed insulated metal roof panels are designed for photovoltaic projects, providing both structural support and reliable insulation. They combine thermal protection, noise reduction, and a clean decorative finish in a single solution. The ribbed interlocking system allows solar modules to be fixed with special clips instead of drilling, protecting the roof and lowering installation costs on large-scale projects.

These insulated metal roof panels can be used in both industrial and residential roofing projects. They are also suitable for public buildings such as schools, hospitals, shopping centers, and community housing. In addition, they are widely applied in roof renovations for old factories and the upgrading of existing buildings.

| Model | BLT-430 |

| Effective width | 430mm |

| Length | 1m-12m (customizable) |

| Sandwich panel thickness | 20mm |

| Structure | Metal face sheets polyurethane core aluminum foil |

| Metal sheet material | Galvalume steel sheet,titanium zinc sheet,Al-Mg-Mn alloy sheet |

| Metal sheet thickness | 0.4mm-0.7mm |

| Metal sheet suppliers | Baosteel,BlueScope,Yieh Phui,Wah Tung,Alliance Steel,etc. |

| Core material | Rigid polyurethane (PUR/PU) Mineral wool (optional) |

| Color | Standard color custom color |

| Surface coating | PE/HDP/PVDF,etc. |

| Lifespan | At least 30 years |

| Applications | Architectural roof and wall cladding |

| Remarks | 1. Installation support is available from our technical team to ensure proper setup 2. All necessary accessories for integrating solar panels with the roofing system are included Customized options are also available to match different project requirements |

- Prefabricated interface for direct photovoltaic installation with integrated insulated metal roof system.

- Special clips secure solar modules to the roof panel without being limited by panel size.

- Eliminates the need for traditional aluminum rails and clamps, cutting both material and labor costs.

- Resistant to strong winds, seismic loads, and water penetration, while providing insulation, noise reduction, durability, and energy efficiency.

- Features self-cleaning properties, strong weather and corrosion resistance, and low maintenance requirements.

- Lightweight design makes installation easier, with no need for heavy lifting equipment, improving overall efficiency.

Metal sheet

- Galvalume steel sheet

Corrosion resistance typically 2–6× higher than regular galvanised steel, with good heat/oxidation resistance and high solar reflectance that helps lower interior temperatures (energy saving). Compared with titanium-zinc and Al-Mg-Mn sheets, it offers a strong cost-effectiveness. - Titanium–zinc sheet

Produced from high-purity zinc (99.995%) alloyed with titanium (0.06–0.20%) and a small amount of copper. Very long service life (~80–100 years in suitable conditions). Forms a protective patina that self-heals minor scratches. Good ductility for curved or complex shapes. - Al-Mg-Mn alloy sheet

Lightweight, high strength and corrosion-resistant, available with many finishes and colours. 100% recyclable; typical service life 50 years.

Coating layer

- PE (Polyester)

Good adhesion and flexibility, moderate chemical resistance. Typically lasts 7–10 years. - HDP (High-Durability Polyester)

Stronger UV and weather resistance, more durable than PE but more cost-effective than PVDF. Service life of 10–15 years. - PVDF (Fluorocarbon coating)

Offers the best colour stability, weather resistance, and protection against fading or chalking. Designed to last 15–20 years.

Need more colors? Feel free to get in touch!

- Lay the sandwich roof panel in place

- Add the special fixing clips

- Position the photovoltaic panel onto the clips

- Secure the solar panel firmly

Tell us about your construction project today!