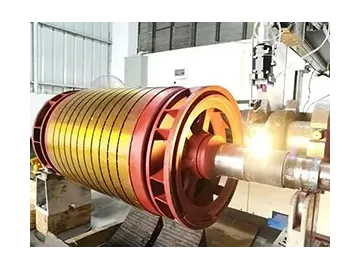

Laser Cladding Machine

Laser cladding machine adopts servo motor for transmission with precise movement, which can be used for welding of carbon steel, stainless steel, aluminum and other metals, motor shafts and cylindrical workpieces (CO2/MAG/MIG, laser and other welding methods), therefore it is widely used in automotive, motorcycle, fire-fighting, electromechanical, renovation, and other fields. An airbag clamping mechanism is adopted to press or reset the workpiece, which can be controlled automatically for easy loading and unloading of the workpiece. Its control system uses LS programmable logic controller (PLC) as the main control system, supplemented by relay control, which realizes the automatic control of welding process. The operator can set the welding speed and other parameters directly through the operation interface to meet the needs of production.

| Model | JXZF-Ø250-Ø800-L3100 |

| Input power | 220V/50HZ |

| Duty cycle | Continuous |

| Rated capacity | 5kW |

| Air pressure adjusting range | 0.2Mpa-0.6Mpa |

| Workpiece thickness | 1mm-5mm |

| Workpiece diameter | Ø250mm-Ø800mm |

| Workpiece length | 100mm-3100mm |

| Torch lifting stroke | 100mm |

Laser cladding machine consists of machine body, welding gun drive mechanism, pneumatic system, electric control system and welding machine and other components.

Body of laser cladding machine is made of following parts:

- Base and bed: a support frame to bear the weight of the machine;

- Main mandrel: used to support the workpiece, to meet the different requirements of product welding;

- Welding trolley: used for welding to ensure that the welding torch smooth traveling and welding.

- Welding speed can be stepless adjusted by servo motor control.

- The 2-axis welding angle adjusting device can adjust and lock different welding angles to meet the requirement.

- The movement, lifting and reset of welding torch is controlled automatically by pneumatic cylinders for stable and reliable workpiece loading and unloading.

- Laser cladding machine can be operated automatically, manually and semi-automatically.

- The workpiece weld seam is corrected by infrared light source. First manually check whether the longitudinal seam is coincident with the infrared ray, make sure that it is coincident and then press button for clamping, which ensures the accuracy and smoothness of the weld seam.

- The PLC is equipped with monitor, and has 1-year warranty.

- The main frame is made of steel plate that is welded and subjected to aging treatment.

- All parts are coated with antirust primer after shot blasting and descaling, or pickling and phosphating, and then plastered with topcoat to enable a neat and beautiful appearance.