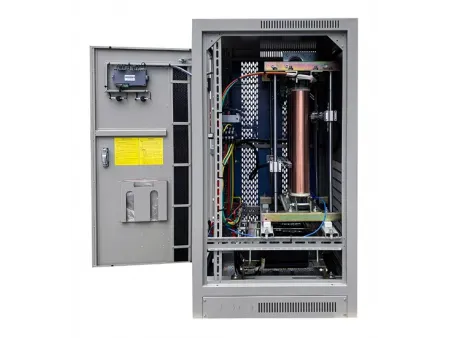

Servo Voltage Stabilizer

Servo motor-controlled voltage regulator for protecting against mains voltage fluctuations and delivering constant voltage for electrical equipment

- Rated capacity: three-phase 10–3600 kVA, single-phase 10–150 kVA

- Phase number: single-phase or three-phase (optional)

- Input voltage: three-phase 380 V (± 20 %), single-phase 220V (±20 %) (customizable upon request)

- Output voltage: three-phase 380V, single-phase 220 V (customizable upon request)

- Voltage regulation accuracy: adjustable within ± 1 % to ± 5 % (factory default ± 3 %)

- Voltage regulation mode: simultaneous three-phase regulation (optional: independent phase regulation)

- Operating frequency: 50 Hz / 60 Hz

- Efficiency: three-phase ≥ 98 %, single-phase ≥ 95%

Servo-controlled voltage stabilizers are designed to ensure stable and reliable power under varying input conditions. They operate through a motor-driven mechanism that continuously adjusts the winding position to maintain consistent output voltage.

These servo-controlled regulators are ideal for facilities where voltage fluctuations occur frequently, or the input power is unstable. They keep the output within a steady range to prevent sudden surges or drops, allowing connected devices to operate smoothly and with better protection against wear or damage.

- Each voltage stabilizing unit keeps the output voltage stable within a small range of ±1%–5% (factory setting ±3%), so even when the input power changes, the supply remains steady and clean. Waveform distortion stays below 1%, ensuring consistent and reliable electricity for all connected equipment.

- The three-phase column design used in the SBW series supports capacities of up to 2400 kVA with efficiency above 98.5%, allowing continuous, stable operation without waveform distortion.

- Three-phase servo motors deliver dependable performance, with an average service life beyond 100,000 hours and stable operation under –40 °C to 50 °C conditions.

- Capable of handling a wide voltage input range and provide consistent power for heavy-duty machinery and for precision instruments such as CNC systems, CT scanners, etc.

- The stabilizers constantly detect changes in the input voltage and make immediate adjustments to keep the output steady, which helps prevent equipment malfunction or damage caused by sudden power fluctuations.

- Equipped with protection against over-voltage, under-voltage, overload, overcurrent, and phase sequence faults, to ensure safe and reliable operation even under unstable grid conditions.

- Fast dynamic response at millisecond level ensures smooth, accurate voltage control. The servo motor, driven through a wear-resistant carbon brush system, allows precise and continuous regulation during rapid load changes.

| Product type | Three-Phase Servo Voltage Stabilizer | Single-Phase Servo Voltage Stabilizer | |

| Model | SBW-#####KVA | DBW-#####KVA | |

| Wiring method | Three-phase, five-wire | Dual-phase, three-wire | |

| Rated capacity | 10–3600kVA | 10–150kVA | |

| Input voltage | Three-phase 380V (±20%) | Single-phase 220V (±20%) | |

| Customizable upon request | |||

| Output voltage | Three-phase 380V (standard) | Single-phase 220V (standard) | |

| Customizable upon request | |||

| Voltage regulation accuracy | Adjustable within ±1% to ±5% (factory default ±3%) | ||

| Operating frequency | 50Hz/60Hz | ||

| Voltage regulation mode | Simultaneous three-phase regulation (optional: independent phase regulation) | Single-phase regulation | |

| Withstand voltage | 2000V for 1 minute without breakdown | ||

| Waveform distortion | ≤0.1% | ||

| Efficiency | ≥98% | ≥95% | |

| Insulation resistance | ≥2MΩ | ||

| Insulation class | Class F (customizable upon request) | ||

| Response time | ≤100ms | ||

| Noise level | 55dB | ||

| Cooling method | Selectable 1. Natural air cooling (AN) 2. Forced air cooling (AF) | ||

| Voltage stabilization time | < 1.5s when input voltage varies within ±10% of rated value | ||

| Operating mode | Dual mode: voltage regulation / mains power operation | ||

| Protection functions | Over-voltage, under-voltage, overload, over-current, short-circuit, mechanical fault, delay output, and return protection | ||

| Display | Digital display for voltage, current, phase sequence, system status, and fault indication | ||

| Operating environment | Ambient temperature | -15℃ to 45℃ | |

| Altitude | ≤2000m | ||

| Relative humidity | ≤95% | ||

| Installation conditions | Free from corrosive gases, vapors, dust, and explosive or conductive media that may affect insulation performance | ||

| Storage temperature | -40℃ to 70℃ | ||

| Enclosure protection level | IP20 as standard (higher protection levels are customizable upon request) | ||

| Standards compliance | YD/T1074-2000/IEC | ||

- Industrial EquipmentUsed in automation control systems, production lines, large electromechanical equipment, metalworking, and metallurgical facilities to ensure stable and reliable power supply.

- AgricultureUsed for protecting control systems and irrigation equipment such as submersible pumps and motor-driven sprinklers. These stabilizers keep the power supply consistent in farms and greenhouses, reducing downtime and preventing damage during continuous operation.

- Medical and Laboratory EquipmentSuitable for precision devices like MRI scanners, diagnostic systems, and laboratory instruments. Stable voltage supply helps maintain accurate operation and protects sensitive electronics from voltage fluctuations in hospitals and research centers.

- Public InfrastructureWidely used in transportation systems, railways, telecom base stations, and broadcasting facilities. Fast voltage response minimizes disruptions, keeping public services running safely and efficiently.

- Commercial BuildingsUsed in shopping malls, hotels, air conditioning systems, lighting networks, and elevators where voltage supply is unstable.

- Other ApplicationsFound in factories, mining and oilfield operations, construction sites, schools, hospitals, and research facilities. Also suitable for computer systems, precision machinery, CT scanners, measuring instruments, imported devices, and automated production lines.

- Power Distribution NetworksSuitable for end users at low-voltage grid terminals where power supply is unstable or fluctuates significantly. Often applied in facilities with large load variations or where high waveform quality is required.

- Power Generation SystemsCompatible with thermal power, hydropower, and small generator units.

Contact

WenlidaWenlida provides advanced voltage regulation and power quality solutions, backed by over 30 years of manufacturing and R&D expertise. Our global partnerships ensure consistent quality and reliable performance in every project. Whether you need voltage regulation, harmonic control, or energy storage support, our experts are here to help. Let’s find the right solution for your application together.

In beverage or milk filling production lines, unstable voltage can lead to inaccurate filling levels and repeated downtime. Which product is recommended to prevent these issues?

An AC voltage stabilizer is the right choice for filling lines. The motor and metering pump in filling machines are very sensitive to voltage changes. When the voltage isn’t stable, the motor speed becomes irregular, which makes the filling volume inaccurate. In milk filling, even a small variation of ±2 ml can exceed the allowed limit, which directly affects product consistency. When a voltage stabilizer responds quickly to changes in the power grid, it keeps the voltage steady, so the filling heads work at a constant speed. This steady operation helps maintain accurate filling volumes, reduces manual adjustments, and keeps the production line running smoothly.

CT and MRI scanners need stable voltage and clean power for accurate imaging. What products can help protect them from fluctuations and harmonics?

The most effective solution is to use a voltage stabilizer together with an Active Harmonic Filter (AHF). CT and MRI systems require a steady and precise voltage supply, as fluctuations beyond ±3% can cause image distortion during scanning. The stabilizer maintains consistent voltage levels, while the APF filters harmonics generated by the equipment’s high-frequency power modules. The combination of a voltage stabilizer and an active power filter (APF) protect circuit boards and ensures clear and accurate diagnostic results that helps reduce maintenance costs over time.

Voltage fluctuations in machining workshops often cause precision errors in lathes, presses, and other equipment. Which product is recommended to maintain stable power and ensure accuracy?

AC voltage stabilizers are the most suitable solution for machining workshops, where equipment such as lathes and presses rely on a stable power supply to maintain precision during operation. When the voltage fluctuates beyond ±5%, it can affect cutting accuracy or cause uneven force in presses. The stabilizer keeps the voltage within the proper range (such as 220V or 380V ±2%), preventing irregular performance and ensuring that machines run smoothly and consistently.

Harmonic interference and voltage fluctuations often cause unstable signal transmission and even damage to equipment in communication base stations. What kind of solution can effectively keep them running smoothly?

A voltage stabilizer used together with an Active Harmonic Filter (AHF) provides the best protection. The stabilizer eliminates the effects of unstable grid voltage, preventing overvoltage or undervoltage damage to the base station’s power modules. Meanwhile, the APF filters out 3rd, 5th, and 7th harmonics that are commonly produced by rectifier modules in communication systems. Together, they help maintain clear and stable signal transmission and keep base stations running continuously without interruptions.

Data centers run on high power, and unstable voltage can cause system crashes while harmonics affect UPS performance. What solution can help keep the servers operating safely and continuously?

The combination of a voltage stabilizer and an Active Harmonic Filter (AHF) is ideal. Data center servers require highly stable voltage, fluctuations beyond ±1% can lead to downtime or data loss. The stabilizer keeps the input voltage constant, while the APF filters high-frequency harmonics generated by servers and switches. This not only helps the UPS system charge and discharge properly but also extends battery life, reduces circuit losses, and lowers the overall energy consumption of the facility.