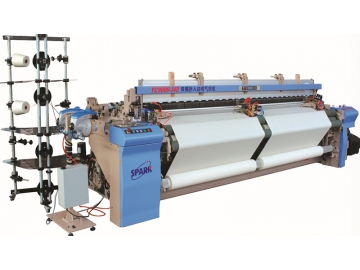

YC600 Air jet loom

The YC600 air jet loom is the perfect choice for producing uncomplicated household, apparel and industrial fabrics with a higher output and lower labor cost than a rapier loom or water jet loom. This air jet loom was developed using a water-jet loom for inspiration, and features an air jet weft insertion mechanism, offering the most competitive price in the market and delivering the highest performance in regard to versatility, flexibility and quality.

In order to provide a stable production performance and reduce the working vibration, Spark has thoroughly innovated the air jet weaving machine — theYC600 air-jet loom features a robust box-type wall structure and a multi-supporting weight balanced beating system. The back rest is designed to allow the warp yarn adjustment for multiple materials (chemical fiber or blended yarn) and improves the weaving capacity.

- The high speed response solenoid valve and optimized air jet control system reduce the air consumption by 35%, ensuring the working stability and extending the service life.

- The high-speed weft insertion system consists of a TOYOTA 810 main nozzle, swing nozzle and sub nozzle.

- Different take up and let off options are available to meet different customer production requirements, including electronic let off, electronic take up, mechanical let off and mechanical take up. For the shedding mechanism, crank shedding, cam shedding, dobby shedding or electronic jacquard shedding is optional.

| Item | Specifications | Spare Parts | |

| Reed Width | Nominal | 150, 170, 190, 210, 230, 250, 280, 340, 360, 390 | |

| Effective | Nominal: 0~60cm (150-250) 0~80cm (>280) | ||

| Weaving Range | Short fiber: ne 80-ne 7 Filament: 22 D- 1000 D | ||

| Weft selection | 1, 2, 3, 4 & 6 Colors | ||

| Motor | Start mode | Super speed start | |

| Press the start/stop button to slow action forward/rear | |||

| Press the link& start button at the same time to start | |||

| Power | 2.8kw, 3.0kw, 3.7kw, 4.5kw, 5.5kw | ||

| Weft insertion | Method | Main nozzle Swing Nozzle Sub nozzle U type reed | WBS(Weft brake system) |

| Control | Import high frequency sub nozzle/ computer program control | ||

| Sub nozzle | Integrated flow sub nozzle | ||

| Feeder | Electric control loop feeder | Balloon prevent device | |

| Beating | Beating motion | Dual oil bath box type 4-bar/ 6bar/ eccentric beating motion | |

| Solid beating system | |||

| Multi support brick and balance weight | |||

| Shedding | Crank/ Plain shedding | ||

| Cam shedding | |||

| Electronic Jacquard shedding | |||

| Dobby Shedding | Upper dobby shedding | ||

| Let Off | Electric servo let off | Double Warp Beam | |

| Dual back beam | |||

| Positive/ negative let off | |||

| Flange dia. | 800, 914, 1000 mm | ||

| Take up | Take up | Electric servo/ mechanical take-up | |

| Fabric rolling | Inside rolling (Max. 600mm)/ Outside rolling | ||

| Temple | Upper/ underneath | ||

| Selvedge | Dual sides planet selvedge/ electric | ||

| Lubrication | Motion box is oil bath, others are centralized lubricating | ||

| Shut down device | Weft breakage | Reflecting double sensor W1, W2 | |

| Warp breakage | Control system warp break detector, LED display | ||

| Others | Selvedge yarn/ yarn end break stop motion | ||

| Shutdown display | Screen display, multi- function shutdown display lights | ||

| Weft cutter | Mechanical cutter, electronic cutter | ||

| Electric control system | High resolution large VGA color touch display, DSP motherboard, WIFI connect. | ||