Beryllium Copper

Request a Quote

Copper Alloy

Copper Alloy

Beryllium copper is an alloy containing small amounts of beryllium, usually between 0.5% to 3%, making it one of the strongest copper alloys.

- Beryllium copper exhibits excellent resistance to corrosion, particularly in air and water, making it suitable for harsh environmental conditions.

- This alloy can be heat-treated and machined into various shapes, showing outstanding performance in the production of precision components.

- Compared to regular copper alloys, Beryllium Copper offers significantly higher strength and can withstand substantial pressure and mechanical loads.

- It maintains strong mechanical properties even at high temperatures.

- Beryllium copper is non-magnetic, making it ideal for use in explosive environments.

- It is highly resistant to wear, making it perfect for components subjected to high wear and tear.

- It can be easily welded and brazed, making it well-suited for precision machining applications.

Specifications

| Beryllium Copper Plate/Sheet | |

| Thickness | 0.1mm-100mm |

| Width | 50mm-1000mm |

| Length | 1000mm-3000mm,or customizable |

| Beryllium Copper Rod | |

| Diameter | 2mm-200mm |

| Length | 1 m-3m,or cut to desired length |

| Beryllium Copper Wire | |

| Diameter | 0.05mm-5mm |

| Delivery Forms | Coiled wire or straight wire |

| Beryllium Copper Tube | |

| Outer Diameter | 3mm-100mm |

| Wall Thickness | 0.5mm-10mm |

| Length | 1 m-3 m |

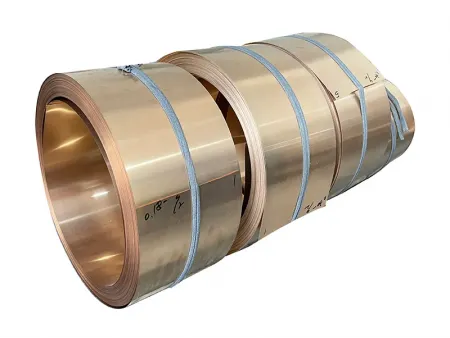

| Beryllium Copper Strip | |

| Thickness | 0.01mm-0.1mm |

| Width | 10mm-300mm |

| Processing Accuracy | ±0.005mm |

Chemical Composition

| Grade | Beryllium (Be) | Nickel (Ni) Cobalt (Co) | Cobalt (Co) Nickel (Ni) Iron (Fe) | Lead (Pb) | Copper (Cu) |

| C17000 | 1.60-1.79 | ≥0.2 | ≤0.6 | - | Rest |

| C17200 | 1.80-2.00 | ≥0.2 | ≤0.6 | - | Rest |

| C17300 | 1.80-2.00 | ≥0.2 | ≤0.6 | 0.2-0.6 | Rest |

Physical Properties

| Density | 8.3g/cm³-8.8g/cm³ |

| Melting Point | 865°C-955°C |

| Electrical Conductivity | 15%-60% IACS (International Annealed Copper Standard) |

| Thermal Conductivity | 105 W/(m·K)-125 W/(m·K) |

| Coefficient of Thermal Expansion | 16.6×10⁻⁶/K (20°C-300°C) |

Mechanical Properties

| Tensile Strength | |

| After Aging Treatment | 930 MPa-1380 MPa |

| Hardness | |

| After Aging Treatment | HRC 38-45 (Brinell Hardness 300-400 HB) |

| Elongation at Break | 4%-20% (depending on the condition of heat treatment) |

| Modulus of Elasticity | 120 GPa-130 GPa |

Chemical Properties

| Beryllium (Be) | 0.2%-2.0% |

| Copper (Cu) | Rest (main element) |

| Others | Nickel (Ni),Cobalt (Co),etc. |

| Corrosion Resistance | Excellent oxidation and corrosion resistance,making it suitable for use in salt spray and marine environments |