Copper & Copper Alloy

Request a Quote

Copper & Copper Alloy Wire

Copper and copper alloys are versatile materials known for their excellent electrical and thermal conductivity, corrosion resistance, and ductility. Copper and copper alloy are some of the most versatile engineering materials available. The combination of physical properties such as strength, conductivity, corrosion resistance, machinability and ductility make copper suitable for a wide range of applications. These alloys are widely used in various industries, ranging from electrical wires to high-performance components in aerospace and marine environments.

Available grades

- Brass: H59, H62, H65, H68

- Beryllium copper: C17000, C17200, C17500

- Cast beryllium bronze: C82000, C82200, C82400, C82500, C82600, C82800

- Chromium zirconium copper: C18150, C18200, C15000

Brass

| Chemical Composition | ||||||

| Grade | Copper (Cu) | Zinc (Zn) | Lead (Pb) | Iron (Fe) | Antimony (Sb) | Bismuth (Bi) |

| | 60.5-63.5 | Rest | 0.08 | 0.15 | 0.005 | 0.002 |

| | 63.5-68.0 | Rest | 0.03 | 0.15 | 0.005 | 0.002 |

| Mechanical Properties | |||

| Grade | Tensile Strength (Rm N/mm²) | Elongation at Break A5 (%) | Thickness |

| H62 | 410-630 | 10 | 0.3-10 |

| H65 | 360 | / | 5-40 |

Beryllium Copper

| Chemical Composition | |||||

| Grade | Beryllium (Be) | Nickel (Ni) Cobalt (Co) | Cobalt (Co) Nickel (Ni) Iron (Fe) | Lead (Pb) | Copper (Cu) |

| | 1.60-1.79 | ≥0.2 | ≤0.6 | - | Rest |

| | 1.80-2.00 | ≥0.2 | ≤0.6 | - | Rest |

| | 1.80-2.00 | ≥0.2 | ≤0.6 | 0.2-0.6 | Rest |

| Mechanical Properties | ||

| Standard | ASTM B196M/ASTM B441 | YS/T 334-2009 |

| High-Strength Beryllium Copper | C17000 | QBe2 |

| C17200 | Qbe1.9 | |

| C17300 | Qbe1.9-0.1 | |

| Qbe1.7 | ||

| High Conductivity Beryllium Copper | C17500 | Qb0.6-2.5 |

| C17510 | Qb0.3-1.8 | |

| Qb0.3-1.5 | ||

Chromium Zirconium Copper

| Physical Properties | |||||

| Density (g/cm³) | Tensile Strength | Hardness | Elongation at Break | Electrical Conductivity | Thermal Conductivity |

| N/mm² | HV | % | (20℃)IACS(%) | (20℃)W/m.k | |

| 8.9 | ≥ 380 | 110-145 | ≥ 15 | ≥ 75 | 330 |

| Chemical Composition | |||||||

| Aluminum (Al) | Magnesium (Mg) | Chromium (Cr) | Zirconium (Zr) | Iron (Fe) | Silicon (Si) | Phosphorus (P) | Impurities |

| 0.1-0.25 | 0.1-0.25 | 0.1-0.8 | 0.1-0.6 | 0.5 | 0.5 | 0.1 | 0.5 |

Selection Criteria

- Corrosion resistance

Choose alloys with higher corrosion resistance for marine or outdoor environments, such as bronze and copper-nickel alloys - Electrical/thermal conductivity

Pure copper or copper-silver alloys are ideal for applications requiring high conductivity - Strength and durability

For structural applications, stronger alloys such as aluminum bronze or brass are preferred - Machinability

For precision and large-scale manufacturing, leaded brass or machinable copper alloys are recommended for better machinability

Applications

- Electrical and electronics industry: Used in applications ranging from household wiring to large power transmission lines in power plants

- HVAC: Essential components like refrigerant piping, evaporators, and condensers

- Building and infrastructure: Roof materials, curtain walls, door and window frames, and other architectural features

- Automotive manufacturing: Engine cooling systems, brake systems, electrical wiring, and more

- Marine engineering: Components resistant to seawater corrosion such as ship hulls and propeller shafts

- Medical equipment: Surgical instruments, dental tools, and other medical devices

- Telecommunications: Copper shielding for fiber optic communication systems

- Instrument manufacturing: Used in brass wind instruments like trumpets and trombones

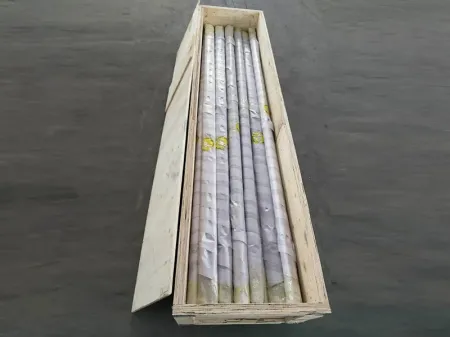

Packaging