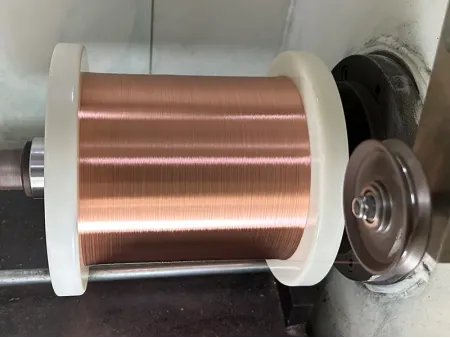

Copper Alloy Conductor

In demanding environments, single-metal conductors often face limitations, making copper alloys a more reliable choice for specific applications. With over a decade of expertise in copper alloy conductors, we have developed a range of specialized solutions, including copper-tin (CuSn), copper-magnesium (CuMg), copper-silver (CuAg), copper-nickel (CuNi), and copper-chromium-zirconium (CuCrZr) conductors. These alloys enhance adaptability to different operating conditions while maintaining essential electrical properties.

Each alloy offers distinct advantages based on application needs. Copper-tin (CuSn) provides superior corrosion resistance, suitable for humid or chemically aggressive environments. Copper-magnesium (CuMg) is a lightweight alternative with high strength and flexibility. Copper-silver (CuAg) improves flexibility while minimizing conductivity loss. Copper-nickel (CuNi) ensures stable electrical performance across varying temperatures due to its low temperature coefficient, and copper-chromium-zirconium (CuCrZr) delivers increased structural strength for heavy-duty applications. Customers can select the most suitable alloy based on their specific operational requirements.