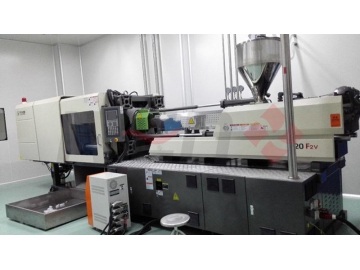

TYM-3038 Liquid Silicone Injection Molding Machine

Features of Liquid Silicone Injection Molding Machine (Single Sliding Board)

1. Our TYM-L3038 Vertical Liquid Silicone Rubber Injection Molding Machine (single sliding board) is highly efficient, energy saving, and requires low cost to operate.

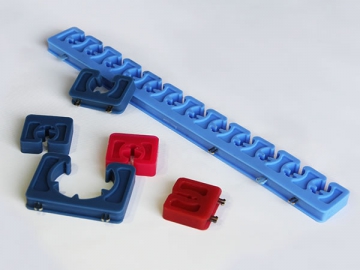

2. The use of the precise cold runner LSR mould ensures the high quality and long lifetime of LSR products.

3. The machine adopts permanent magnet synchronous servo motors with quick response. The output flow of the power mechanism matches the flow of the actuating mechanism, so there is no high-pressure throttling loss.

4. Quality oil pump, proportional valve and magnetic valve from world famous brands help guarantee excellent control of the hydraulic functions.

5. New TYM series controller, adjustable parameter settings, and multiple electronic rulers that monitor each action executed, can guarantee the reliability, stability and accuracy of the machine's operation.

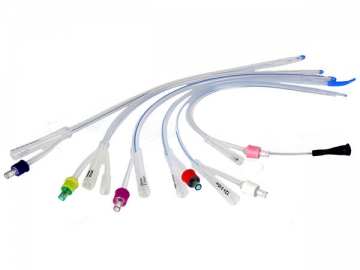

6. Our self-developed direct pressure injection barrel is more suitable for the moulding process of the LSR material.

7. Our self-developed full stainless steel pumping unit and fixed displacement pump can guarantee accurate proportion of 1:1 (A:B) for feeding the material.

| Model Item | Tym-l3038 Note: assuming the LSR density : 1.2g/cm3 |

| Injection unit | |

| The diameter of injection pail (mm) | 20 |

| The length of injection pail (mm) | 150 |

| Shot volume(theoretical) (ml) | 120 |

| Injection rate (ml/s) | 25 |

| Injection pressure (t) | 12.5 |

| Nozzle radius (mm) | R19 |

| Clamping unit | |

| Clamp force (t) | 95 |

| Opening stroke (mm) | 400 |

| Template dimension (w×h) (mm) | 300×380 |

| Min. Moldboard distance (mm) | 150 |

| Ejector stroke (mm) | 150 |

| Ejection force (t) | 7.8 |

| Others | |

| Pump pressure (mpa) | 25 |

| Pump motor power (kw) | 7.5 |

| Heating power (kw) | 9 |

| Machine dimension(l×w×h) (mm) | 2800×1700×3000 (including the dosing unit) |

| Mould orientation ring diameter (mm) | Φ100 |

| The specification of the dosing unit (kg) | 200kg/20kg |

| Machine weight (t) | 2.8 |

Equipment Maintenance

1. As correct application method and good maintenance is an important guarantee for the machine's long-term and steady working. It is necessary to give good maintenance to the machine and thus can extend its service life and ensure the normal use.

2. Please clean the outer cover, inwall, protective shield every day for every axis of the machine, and also clean the sundries, which can avoid machine block caused by foreign material.

3. Please check if there is air leakage on the pipe joint and the sealing elements for the air cylinder. If there is breakage on the air pipe, then please change that in time.

4. Please ensure that the ventilation of the electrical cabinet is good and avoid heavily breaking or pressing of the electronic wire and cable.

5. Please change the sealing elements and wearing parts regularly.

6. Please keep the environment clean and clean the machine and do the lubrication on the moving parts regularly.

7. Please regularly check whether every fixed part is loosening or not and every moving parts is good or not..

8. The hydraulic oil for the hydraulic system is 46# antifriction hydraulic oil. In general, you need to add it until it is enough, which is based on the detailed waste, and check if the sealing of the water cooling tank and the foot cage is good.

9. Please clear in depth the cover of the equipment and the dust cover every half a month, and wipe the inside and the outside of every parts.

10. Please clean the static mixer and the nozzle regularly every 1 to 3 months.

11. Please examine and repair the machine and the electronic parts every half a year and repair the machine in deep every single year.

12. Please don't dismantle every parts of the machine and report if there is something wrong and have the maintenance man to repair it.