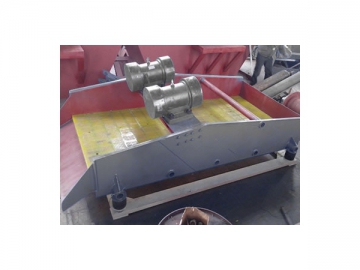

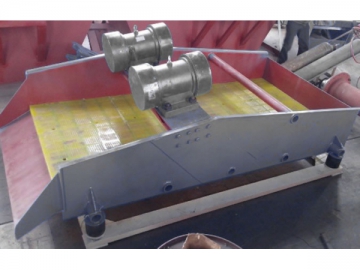

Dewatering Screen

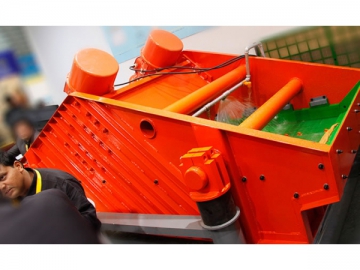

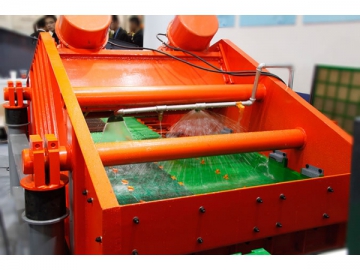

This series of dewatering screens are designed by DingBo for maximum efficiency in classifying and dehydrating materials. The screening machines are expertly engineered to process tailings, coal materials, ores, building materials and materials in chemical industries.

Advantages

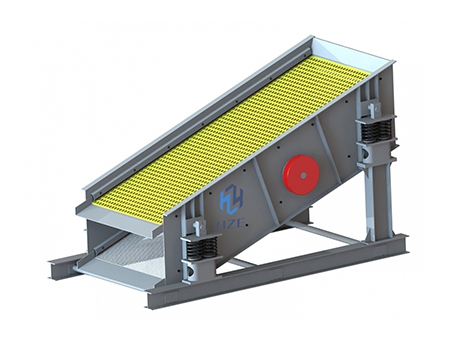

1. Thedewatering devices use a vibrating screen with an adjustable amplitude to meet different requirements.

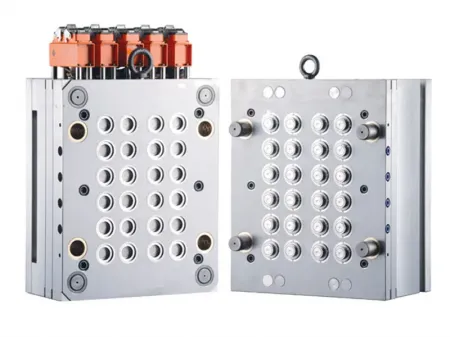

2. Equipped with highly wear-resistant screens.

3. 45 degree incline feeding mouth that uses centrifugal force to maximize dewatering.

4. Thescreening devices have an easily adjustable screen to realize maximum output and efficiency.

5. High strength ring groove rivets to avoid welding defects and maintain structural integrity.

6. Low alloy Q345 steel construction.

7. Equipment can operate at temperatures as low as -40℃

| Model | Vibration frequency(r/min) | Screen Mesh Size(mm) | Capacity(t/h) | Power(kW) | Overall dimension(L×W×H)(mm) | Wei ght(t) |

| 1450 | 0.1-2 | 10-30 | 2×1.5 | 3440×1680×2310 | 2.4 | |

| 1450 | 0.1-2 | 15-45 | 2×1.5 | 3440×1880×2310 | 2.6 | |

| 1450 | 0.1-2 | 20-60 | 2×2.25 | 3440×2180×2400 | 3 | |

| 1455 | 0.1-2 | 30-80 | 2×3.7 | 4140×2480×2530 | 4 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.