Vibrating Screen

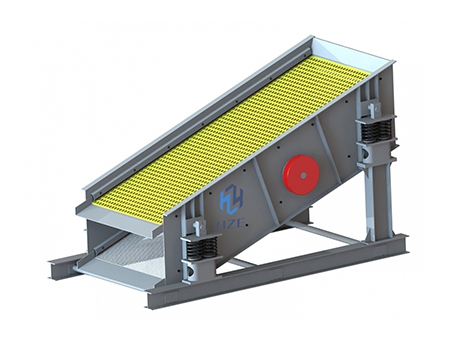

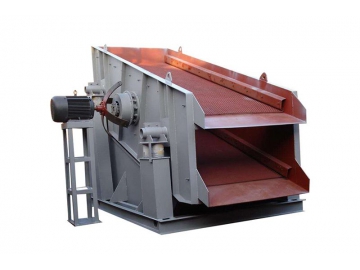

YZS series vibrating screen is a new type screening machine, it is specially designed for separating stone in quarry. It also can be used as the separator in coal ore dressing, mineral dressing, building materials, electric power, chemical and other fields. It has the advantages of advanced structure, strong vibrating force, low noise, easy maintenance, durable and so on.

For screen grading, materials are separated mechanically on screen plates that have rolling bearings that can withstand the stress of high loads. The output of the screen depends on the inclination of the screen, the machine's RPM and vibration frequency. We can design and supply all ranges of vibrating screens according to specific capacity and other requirements.

Features1. Large processing capacity and high screening efficiency.

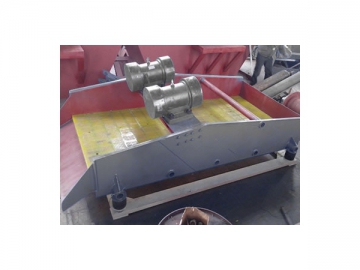

2. Our high frequency vibrating screen uses cylinder-type eccentric shaft vibration exciter and consistent amplitude vibrator, which is easy to maintain.

3. This vibrating sieve adopts spring steel wire mesh and perforated metal sheet to make sure the long service life.

4. Rubber spring is used by our screening machine, which can make the vibrating smoothly with low noise.

Working Principle

The vibrating screen is equipped with screen box, screen, vibrator, spring damper, undercarriage, and so on. Screen machine is made by high quality steel plate, its side plates, crossbeams, exciter seat are connected by high strength bolt or ring groove rivet. The vibrator is installed on the side plate of screen box, and rotated at a high speed driven by motor through triangle belt, and provided a centrifugal inertial force to vibrate sieve. The materials on the inclined surface of screen will impulse screen box to produce a continuous throwing motion. The materials and screen surface encountered the particles of materials that smaller than screen will through the screen to achieve classification of materials.

| Model | ScreenSpec (mm) | Screen Deck | Screen Mesh (mm) | Feeder Opening(mm) | Capacity (t/h) | Power (kw) | Vibrating Frquency (r/min) | Double Amplitude (mm) |

| 1200x3700 | 2 | 4~50 | ≤200 | 10~80 | 15 | 960 | 4~8 | |

| 1200x3700 | 3 | 4~50 | ≤200 | 10~80 | 15 | 960 | 4~8 | |

| 4800x1500 | 2 | 3~100 | ≤400 | 30~275 | 15 | 870 | 5~9 | |

| 4800x1500 | 3 | 3~100 | ≤400 | 30~275 | 15 | 870 | 5~9 | |

| 4800x1800 | 2 | 3~100 | ≤400 | 56~330 | 18.5 | 870 | 5~9 | |

| 4800x1800 | 3 | 3~100 | ≤400 | 56~330 | 18.5 | 870 | 5~9 | |

| 6000x1800 | 2 | 3~100 | ≤400 | 65~586 | 22 | 870 | 5~9 | |

| 6000x1800 | 3 | 3~100 | ≤400 | 65~586 | 22-30 | 870 | 5~9 | |

| 6000x2100 | 2 | 3~100 | ≤400 | 81~720 | 30 | 730 | 5~9 | |

| 6000x2100 | 3 | 3~100 | ≤400 | 81~720 | 30~37 | 730 | 5~9 | |

| 6000x2400 | 2 | 3~150 | ≤400 | 100~810 | 37 | 770 | 5~9 | |

| 6000x2400 | 3 | 3~150 | ≤400 | 100~810 | 37 | 770 | 5~9 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.