C-Frame Rubber Injection Molding Machine

Rubber Forming Machine, Rubber Molding Machine, Injection Molding Machine, Injection Press, Vertical Injection Machine

XZL C-frame rubber injection molding machine, also called as corner connector for automobile rubber seal strip, is an optimal choice for various rubber seal strips and natural rubber or synthetic rubber. The C-frame structure, high-strength wallboard design, and extremely-small deformation makes it suited to be operated. The XZL series rubber injection press of Huatai has been exported to Argentina, Mexico, France, Poland, Italy, India, and Turkey.

Customization Service

1. Near 45 years' manufacturing experience allows Huatai to be competent offering comprehensive rubber injection and molding solutions and providing customization service for clients.

2. We can set mold protection devices at different places upon clients' request.

3. Before production starts, we will communicate with clients to know exactly the specific components and parameters like platen dimension, clamping force, and injection volume they want.

4. Huatai has collected 18 highly-experienced technical engineers who have being working in the rubber injection press industry for 20 years. Under their support, we only need clients to provide the drawings and their requirements to finish the customization process.

Details of XZL C-Frame Rubber Injection Molding Machine

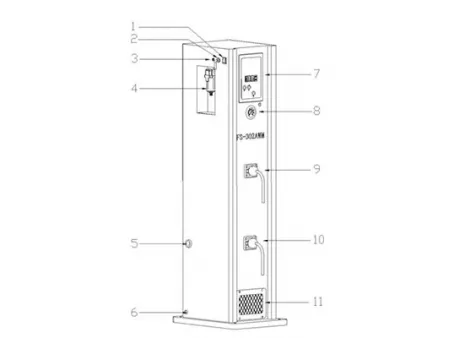

1. Control System

Users can choose the hydraulic supporting part, the auxiliary starting part, the integrated mold ejection system, the dual-station remote control, or the integrated remote control system for their rubber injection machine.

2. Accurate Injection System

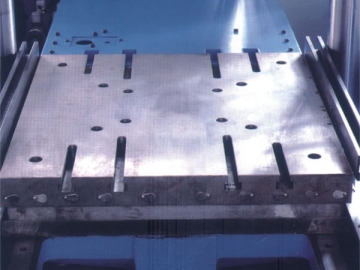

3. High-Efficiency Clamping Unit

4. Multi-Language Display

You can choose the English, Chinese, or Japanese language modes.

5. Movable Pre-Molding Unit

6. Protection Mechanism

● We have introduced the photoelectric safety door, the security switch, and the low pressure mold protection device to ensure the safety of the equipment.

● The rubber injection machines are packed with wooden boxes to protect them during delivery.

● If a machine problem arises and a valid request is received, we will send our service personnel to the production site without delay.

| Model | XZL-100 ×270 | XZL-160 ×270 | XZL-200 ×400 | XZL-300 ×400 | XZL-200 ×800 | |

| Injection unit | Injection capacity (cm3) | 100 | 160 | 200 | 300 | 200 |

| Injection speed (cm3/s) | 32 | 44 | 55 | 30 | 65 | |

| Plunger diameter (mm) | 25 | 32 | 34 | 38 | 34 | |

| Screw diameter (mm) | 30 | 30 | 30 | 30 | 30 | |

| Screw length/diameter (L/D) | 12:1 | 12:1 | 12:1 | 12:1 | 12:1 | |

| Clamping unit | Clamping force (KN) | 270 | 270 | 400 | 400 | 800 |

| Stroke (mm) | 295 | 295 | 310 | 295 | 410 | |

| Intervals between platen (mm) | 425 | 425 | 430 | 425 | 605 | |

| Min mold thickness (mm) | 130 | 130 | 120 | 130 | 200 | |

| Platen size (mm) | 300 ×300 | 300 ×300 | 450 ×450 | 450 ×450 | 500 ×700 | |

| Other parts | Motor power (kw) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Heating power of platens (kw) | 5.4 | 5.4 | 9.6 | 9.6 | 10.8 | |

| Dimension (m) | 2.1 ×1.0 ×2.6 | 2.1 ×1.0 ×2.6 | 2.1 ×1.3 ×2.6 | 2.1 ×1.3 ×2.6 | 2.8 ×1.3 ×3.0 |

After Sales Service

1. Those broken spare parts are offered free of charge within 1 year since the delivery.

2. If clients need, we will send the consumable parts with the injection press or deliver them by express.

3. All of our after service personnel have accumulated over 10 years' working experience. If an installation or repairing service is needed, we will arrange our professionals to the production site.