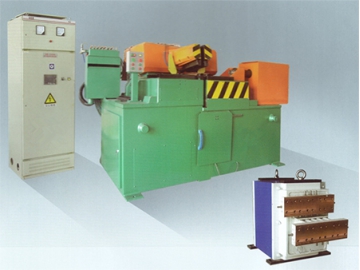

DC Electric Resistance Welding Machine

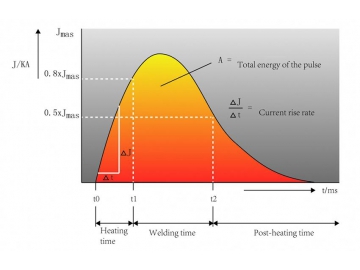

DC electric resistance welding machines use the heat generated by the contact resistance between the electrodes to melt metal, and thus, achieve welding of copper, aluminum, stainless steel and other metals. It has a great stability with a 1000HZ working frequency and 1ms response time, making it applicable for use in hardware products, automobiles, and electric appliances.

Compared to an AC resistance spot welding machine, the DC electric resistance welding machine has the following prominent features:

1. Larger response speed and better stability.

2. Larger welding speed.

3. Better energy-saving ability.

- Power: 80KVA

Welding ability: aluminum plates with thickness of 1+1mm and iron plates with thickness of 2+2mm. -

- Power: 120KVA

Welding ability: aluminum plates with thickness of 1.5+1.5mm and iron plates with thickness of 3+3mm.

-

- Power: 170KVA

Welding ability: aluminum plates with thickness of 1.8+1.8mm and iron plates with thickness of 3.5+3.5mm.

-

- Power: 230KVA

Welding ability: aluminum plates with thickness of 2.5+2.5mm and iron plates with thickness of 4.5+4.5mm.

-

- Power: 280KVA

aluminum plates with thickness of 3+3mm and iron plates with thickness of 5.5+5.5mm.

● High quality and highly efficient welding performance with a 98% power factor

● Three-phase input balance with the ability to reduce power grid impact. Zero impedance with a DC output

● The current is monitored in real time for the current consistency of each welding spot.

● Features an abnormal current alarm to ensure safety.

● The upper and lower arms are an integral C type structure, with a high rigidity and stable welding quality.

● The electrode is made of high quality conductive material, which significantly reduces the circuit impedance in order to achieve a highly efficient, energy saving welding process

● Equipped with pressure adjusting device and pressure gauge, easy to observe and operate.

● The tool box is designed in the remaining electric box space for easy tool storage.