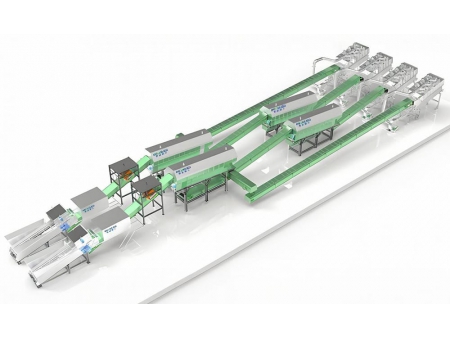

Landfill Waste Treatment System

Stale garbage refers to remaining non-degradable garbage that has been in landfills for long periods of time and has not broken down. It is usually composed of plastics and metals.

Landfill waste treatment system primarily consists of equipment such as rotary screens, sorting devices, and magnetic separators. Upon arrival, the waste first passes through the rotary screen, which separates the material into coarse oversized fractions and finer undersized fractions. The undersized material is humus soil, while the oversized fraction undergoes air separation to divide it into heavy and light materials. The light fraction mainly consists of waste plastics, whereas the heavy fraction includes humus soil and construction debris. Iron metals are then removed from the humus soil and construction debris using magnetic separators.

The processed material from the landfill waste treatment system is classified into four main categories:

- Waste plastics (can be used for incineration power generation or as fuel in cement kilns)

- Humus soil (suitable for landscaping or backfilling)

- Construction aggregates (can be recycled as aggregate for building materials)

- Metals.

- This highly-automated waste sorting plant features a capacity of 100 tons/hour, meaning it can typically process an entire landfill within one year.

- The sorting system increases landfill efficiency and land reuse.

- This waste sorting plant features strict requirements for weather and corrosion resistance for field applications, which is why we have constructed it using galvanized steel that is adaptable to a variety of harsh weather conditions.

- Since the waste sorting plant needs to be transferred to other landfills after sorting waste in one landfill, it is designed with a mobile chassis for convenient disassembly and transportation to the next landfill.