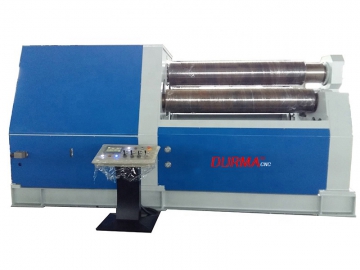

Hydraulic Guillotine Shearing Machine

The hydraulic guillotine shearing machine features a framework structure made using an all steel welding process, a four-angle eight-sided rectangular guide and hydraulic preload with a high precision and durability. The hydraulic system uses a two-way cartridge integrated valve, movable worktable and the photo-electric safety device digital display to display the corresponding route. It also features an upper sliding block and lower hydraulic cushion, both of which are movable, and an adjustable working pressure during the pressing process according to working requirements.

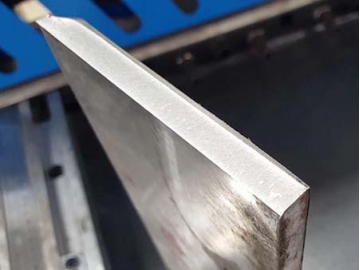

The hydraulic guillotine shearing machine is exceptionally durable with a high shear force, making it ideal for plate cutting at a thickness of more than 16mm, and is widely used in the manufacturing of automobiles, tractors, locomotives, ships, electric motor gauge instruments and more.

Features- The welding machine body undergoes a vibration aging treatment for a high toughness and processing precision and will maintain long term working precision.

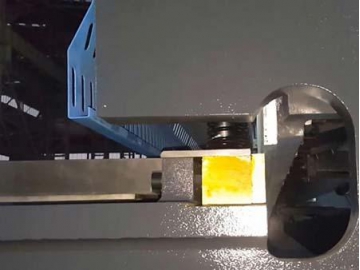

- The rolling guide way with 3-point support ensures the upper blade holder rolls with no vibration, and the blade gap remains adjustable via the manual wheel.

- The movable blade support and the four edges make it easier to adjust the blade gap, extend the blade service life, and improve the cutting quality.

- The hydraulic guillotine shearing machine uses a tandem hydraulic cylinder synchronizing system. By adjusting the cylinder flow, the shear angle is easily adjusted to adapt to different thickness plates.

Use a mechanic metal sheets stopper and electronic register to adjust the metal sheet position.

Use mechanic metal sheets stopper and electronic register to adjust the position of metal sheets.

Parameters| Model | Shear plate thickness | Shearableplate width | Number of trips | Back gauge range | Shear angle | Main motor power |

| mm | mm | Times/min | mm | ° | kw | |

| 6×2500 | 6 | 2500 | 20-25 | 600 | 0.5-1.5 | 7.5 |

| 6×3200 | 6 | 3200 | 16-25 | 600 | 0.5-1.5 | 7.5 |

| 6×4000 | 6 | 4000 | 14-25 | 600 | 0.5-1.5 | 7.5 |

| 6×5000 | 6 | 5000 | 10-15 | 800 | 0.5-1.5 | 7.5 |

| 6×6000 | 6 | 6000 | 10-15 | 800 | 0.5-1.5 | 11 |

| 8×2500 | 8 | 2500 | 18-25 | 600 | 0.5-1.5 | 11 |

| 8×3200 | 8 | 3200 | 16-25 | 600 | 0.5-1.5 | 11 |

| 8×4000 | 8 | 4000 | 12-25 | 600 | 0.5-1.5 | 11 |

| 12×2500 | 12 | 2500 | 12-20 | 600 | 0.5-2 | 15 |

| 12×3200 | 12 | 3200 | 12-20 | 600 | 0.5-2 | 15 |

| 12×4000 | 12 | 4000 | 12-20 | 600 | 0.5-2 | 15 |

| 16×2500 | 16 | 2500 | 10-15 | 800 | 0.5-2.5 | 18.5 |

| 16×3200 | 16 | 3200 | 10-15 | 800 | 0.5-2.5 | 18.5 |

| 16×4000 | 16 | 4000 | 8-15 | 800 | 0.5-2.5 | 18.5 |

| 20×2500 | 20 | 2500 | 8-12 | 800 | 0.5-2.5 | 30 |

| 20×4000 | 20 | 4000 | 8-12 | 800 | 0.5-2.5 | 30 |

| 25×2500 | 25 | 2500 | 6-10 | 800 | 0.5-3.5 | 37 |

| 25×3200 | 25 | 3200 | 6-10 | 800 | 0.5-3.5 | 37 |

| 25×4000 | 25 | 4000 | 6-10 | 1000 | 0.5-3.5 | 37 |

| 32×2500 | 32 | 2500 | 6-8 | 1000 | 0.5-3.5 | 45 |

| 32×3200 | 32 | 3200 | 6-8 | 1000 | 0.5-3.5 | 45 |

| 40×2500 | 40 | 2500 | 4-8 | 1000 | 0.5-3.5 | 75 |