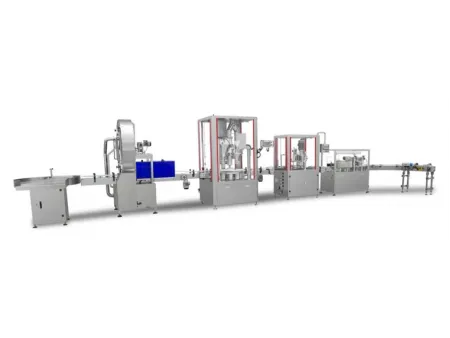

Automatic Milk Powder Filling Line

The automatic milk powder filling line is a customized canning production line designed according to customer requirements, suitable for canning milk powder and protein powder. The production line consists of a bottle unscrambler, bottle washer, can filling and sealing machine, coding machine, and bottle collector. Optional equipment includes a vacuum nitrogen flushing can seamer. The equipment integrates mechanical, electrical, and pneumatic components, controlled by PLC, featuring compact structure, reasonable design, fully automated operation, automatic lid placement, and sealing. The fully automatic can seamer operates at 2-3 times the speed of semi-automatic sealing equipment.

- Filling Volume: 100-1000g

- Can Size: #300, #307, #401, #502

- Can Height: 60-260mm

- Sealing Speed: 12-14 cans per minute (single unit of double head can sealer)

- Filling Accuracy: ±1 to 1.5g

- Oxygen Content: ≤3%

- Power Supply: 380V, 50Hz, three phase

- Power: 48.33kW

- Compressed Air: 1.45m³/min

- Air Pressure: 6kg/cm²

- Nitrogen Gas: purity >99.99%, pressure 0.4Mpa, 10m³/hour per unit (3 sealing machines require 30m³/hour)

- Line Speed: 12-48 cans per minute (depending on quantities of nitrogen flushing vacuum sealing machines, e.g. 36 cans per minute can be achieved by using 3 double head can sealers)

- Suitable for various round cans such as tin cans, aluminum cans, and paper cans.

- Integrated lid control device: lids are supplied only when cans are present.

- Sealing rollers made of 304 stainless steel, offering high hardness, wear resistance, and rust resistance, ensuring excellent sealing performance.

Automatic can unloading, sorting, and sterilization, dual-head weighing and filling, automatic can distribution, vacuum nitrogen flushing and can sealing, automatic can cleaning (static removal, dust cleaning), automatic coding, can flipping, lid pressing, manual or automatic boxing, etc.

Automatic Can Sealing Machine (Can Seamer)

The can seamer is designed with a non-rotating can body to protect the product and can body. It offers high processing precision, superior sealing quality compared to similar products from other manufacturers, and production efficiency 2-3 times that of semi-automatic sealing machines.

- Products: milk powder, protein powder, nutrition power, other powdered products

- Can Capacity: 100-1000g

- Can Size: #300, #307, #401, #502

- Can Height: 60-260mm

- Single Machine Speed: 6-10 cans per minute

- Sealing Speed: 12-14 cans per minute (single unit of double head can sealer)

- Filling Accuracy: ±1 to 1.5g

- Oxygen Content: ≤3%

- Power Supply: 380V, 50Hz, three phase

- Power: 48.33kW

- Compressed Air: 1.45m³/min

- Air Pressure: 6kg/cm²

- Nitrogen Gas: purity >99.99%, pressure 0.4Mpa

Automatic Unscrambler

Used for automatic sorting, orienting, and conveying of various milk powder cans. It features high-speed sorting, quick and easy changeover for different products, and is suitable for plastic bottles, glass bottles (round bottles). Widely used in pharmaceutical, chemical, food, and beverage industries, and can be integrated with different automatic packaging lines.

Can Cleaning Machine

The GHXP ion wind can washer, improved and perfected based on previous models from other manufacturers, features a beautiful appearance, reasonable layout, simple structure, easy operation, and stable production. Suitable for washing the inside and outside of round bottles or specially shaped bottles with shoulder supports. It cleans the inner wall of the can by blowing air after flipping the can to meet food hygiene requirements.

Features- Unique structure, fixed bottle cleaning with flip track, low bottle loss rate.

- Reasonable cleaning process, high bottle cleanliness after washing.

- Able for operating independently or to be used in a linked production line.

Powder Filling Machine

Designed and developed according to the latest GMP standards, this bottle (can) filling machine, with a height of 2 meters, integrates filling, weighing, and conveying, suitable for measuring and filling materials like milk powder.

Utilizes a dual-speed auger filler, allowing flexible control of feeding method and speed, achieving higher measurement accuracy.

Nitrogen Flushing Vacuum Sealing Machine

This machine is a single-seal head fully automatic can seamer with two pairs (four) of sealing rollers. It is used for sealing empty or filled round cans of various sizes made of tinplate or aluminum. Suitable for sealing milk powder and other food products. By replacing the sealing head die and other corresponding can-shaped accessories, it can seal various round cans of different specifications.