Auto-Positioning Balancing Machine

QZD-100

Dynamic balancing machine with automatic positioning for workpieces with diameter of up to 800mm and weight of 5-100kg

These automatic positioning balancing machines combine precision engineering, intelligent control, and software-based data processing. They are designed to measure and correct rotor unbalance with high accuracy. By analyzing data from the measuring system, they automatically locate the unbalance position, removing the need for manual angle finding. Thanks to their automatic positioning function, they can be used across a wide range of rotors that require precise balancing.

Widely used for dynamic balancing of motor rotors and other long-shaft components. Typical applications include separator rotors, oil press rotors, rolls, paperboard machine rotors, crushers, and a variety of agricultural machinery rotors such as straw returning and corn harvesting machines.

| Workpiece weight | 5-100kg |

| Max. workpiece diameter | Ø800mm |

| Journal diameter of workpiece | Ø10-Ø90mm |

| Distance between two bearing supports | 120-800mm |

| Balancing speed | 300-3000r/min |

| Motor power (servo motor) | 3.0kW |

| Belt drive mode | Underslung belt drive |

| Number of planes | Possible to select between single plane and two planes, and select between weight adding and removing |

| Bearing precision class | P5 |

| Machine length | 1000mm |

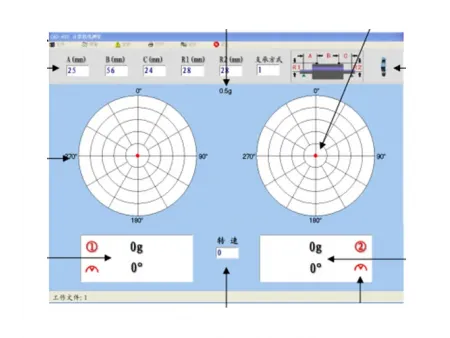

| Electronic measuring system | ZL-210 dynamic balancing measuring system (touch screen) |

| Min. achievable residual unbalance (eMar) (per plane) | ≤0.2g.mm/kg |

| Unbalance reduction ratio (URR) | 95% |

- Measures workpíeces unbalance quickly and accurately, with measuring times as short as 3–5 seconds and accuracy up to 1 mg.

- Automatically stops the rotor at the specified unbalance angle, making operation easier and reducing errors caused by limited operator experience.

- Highly automated compared with traditional balancing machines, requiring no marking and positioning the unbalance angle on its own to reduce workload and correction errors.

- Fast measuring speed significantly shortens the balancing process and helps improve overall production efficiency.