AWS E6010

Welding Rod / Welding Wire / Carbon Steel Welding Wire

Introduction:

The E6010 carbon steel electrode is produced with a cellulose potassium coating that produces beautiful welds after vertical downward welding. The welding wire creates less slag and provides high welding efficiency.

Applications:

The carbon steel welding rod is suitable for edge and butt welding, fillet welding and lap welding on thin, low carbon steel plates. This type of welding is utilized in the production of air ducts, oil tanks and automobile exterior panels.

Chemical Composition of Deposited Metal (%):

| Chemical Composition | C | Mn | Si | S | P |

| Guarantee Value | ≤0.20 | 0.30~0.60 | ≤0.30 | ≤0.035 | ≤0.040 |

Mechanical Properties ofDeposited Metal:

| Test Item | R m (MPa) | R eL (Mpa) | A(%) | KV 2 (J) |

| Guarantee Value | ≥420 | ≥330 | ≥22 | ≥27(-30 ℃ ) |

| General Result | 440~500 | ≥340 | 22~30 | 50~90(-30 ℃ ) |

Reference Current (AC, DC):

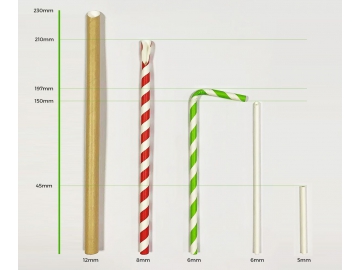

| Electrode Diameter(mm) | φ3.2 | φ4.0 | φ5.0 |

| Welding Current (A) | 80~140 | 130~210 | 170~230 |

X-ray Radiographic Inspection:

ⅡDegree

Packing Details:

In 20kgs/net cartons, consisting of 8 boxes x 2.5kgs for 2.5mm, & 4 boxes x 5kgs for other sizes.

With/ without pallets (fumigation-free pallets) upon customer’s request.

Instructions:

1. If the electrodes become damp in humid environments, they must be baked under 80℃ for 1.5 hours before welding.

2. The stains on the weldments, such as oil stains, rust, moisture etc., must be cleared away before welding.

3. The electrode weaving should not be too wide and the strength of the arc should be suitable.