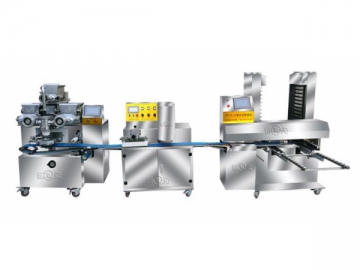

Profile Production Line

Here at Keewa, we not only offer high quality, cost effective extrusion solution for drinking straws, but we also deliver a productive solution for plastic profile production. The JH09 series profile production line is what offer to make hard tubes and small profiles. It functions as a complementary machine for our JH01 series drinking straw extrusion line while providing different cooling, sizing, pulling and cutting methods. Specifically, the profile extrusion line employs vacuum cooling and sizing, split pulling and cutting designs

- Hydraulic Cutter

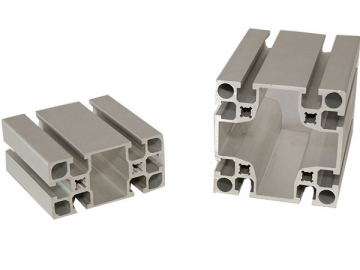

- Samples

- Hydraulic power unit

- Samples

- Belt traction pulling machine

- Belts

- Vacuum Water Tank

- Chiller

With the help of dies, the plastic extrusion machinery can produce hard tubes in more than 0.5mm thickness and high roundness. In addition, it can be used to make mini-shaped profiles for home appliances, decoration, automotive, tools and other industries.

Characteristics of the Profile Production Line

1) Pulling and cutting machine applies PLC and servo control, ensuring high automation.

2) It is easy to operate at a stable running speed.

3) Products have a high dimension consistency

Optional: Hydraulic or pneumatic cutting

Technical Parameters| Model | |

| Capacity | >60Kg/h |

| Speed | >2-100m/min |

| Screw | 55/60/65(optional) |

| Total power | 25-30Kw(380V) |

| Dimension (L ×W ×H) | 12000 ×2000 ×1800mm |

| Weight | 2000Kg |