Flexo Printing Press, FY Series

Request a Quote

Servo Driven In-Line Flexographic Printing Machine for Paper and Cardboard Printing

- Printing repeat: 380mm-800mm

- Max. unwind diameter: 60'' (1524mm)

- Max. rewind diameter: 60" (1524mm)

- Max. mechanical speed: 260m/min (853fpm)

- Substrate: 25-400gsm

Our FY series in-line flexographic printing machine is a fully servo controlled electronic line shaft gearless flexo printing press suited for a variety of applications including paper cup blank printing, paper bag printing, food & beverage packaging printing, pharmaceutical box printing, etc. The printing press combines servo driven sleeve system and stable tension control system, and offers a printing width range of 660-1450mm. A single machine of this series flexo printing press is capable enough to handle high-quality printing on substrates ranging from lightweight paper to heavyweight cardstock.

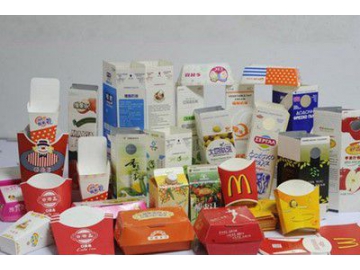

Printing Examples

Custom Printed Food Packaging Supplies

Custom Printed Paper Cups

Printed Paper Cup Blanks & Paper Cups

Applications

- Food & Beverage Packaging Printing

- Paper Cup Blank Printing

- Paper Bag Printing

- Pharmaceutical Box Printing

Features

- Full-servo control, shaftless transmission and gearless design, satisfying various customers’ needs;

- Machine body is constructed by casting process, ensuring robust structure and smooth operation;

- Servo drive allows user to print on various substrates, meeting more printing applications needs;

- Gearless servo drive transmission delivers wider flexo printing applications without printing pitch restrictions of 1/8" (3.175mm), efficiently avoiding banding defect;

- Servo control guarantees precise register in both longitudinal and transverse directions;

- Closed-loop tension control system provides high tension stability in roll unwinding or rewinding;

- Fully automatic web guiding helps automatic guiding of a continuous web;

- Configured with pre-register and auto-register control, production speed and qualification rate can be significantly increased;

- Easy-to-use control console allows to achieve automatic operation, and the operation data is clearly shown via user interface;

- Fault diagnosis system assists users in quick troubleshooting;

- Automatic butt splicer is optional for non-stop unwinding and rewinding;

- Remote communication function is configurable to realize remote fault diagnosis;

- More optional configurations for your individual demands, such as automatic cleaning unit, etc.;

Details

Servo motor

Sleeve

Automatic web threading unit

Automatic web threading unit

Printing unit

Printing sleeve

Chambered doctor blade

Model Options

-

- Max. web width

- 34.25'' (870mm)

-

- Max. printing width

- 32.67'' (830mm)

-

- Max. web width

- 37.00'' (940mm)

-

- Max. printing width

- 35.43'' (900mm)

-

- Max. web width

- 40.16'' (1020mm)

-

- Max. printing width

- 38.58'' (980mm)

-

- Max. web width

- 44.09'' (1120mm)

-

- Max. printing width

- 42.52'' (1080mm)

-

- Max. web width

- 51.57'' (1310mm)

-

- Max. printing width

- 49.21'' (1250mm)

-

- Max. web width

- 57.87'' (1470mm)

-

- Max. printing width

- 55.51'' (1410mm)