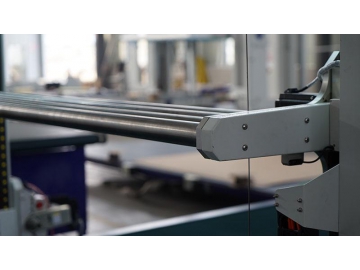

Foam Cutter (Vertical CNC Contour Cutting Machine, Model V6)

Uses

This machine can cleanly cut almost any wanted geometric profile, which can then be used in a number of industries, including automotive, upholstery, packaging, buildings, daily use and more. Its main use cuts sheets vertically into a variety of shapes.

Materials that can be cut

Polyurethane, HR CMHR, PU flexible foam, sticky foam, latex, Basotect ®, rebond foam, polyethylene.

Shapes

The vertical CNC foam cutter can cut foam into wavy, curved, regular, and irregular shapes.

| Standard | O ption | |

| Length of the foam block | 3000mm | 4500mm |

| Height of the foam block | 1250mm | |

| Width of the foam block | 2200mm | |

| Work table | Conveyer belt worktable | |

| AC power | 380V 3 phase 4 wire | |

| Total power | 5KW | |

| Cutting precision | ±0.5mm | |

| Cutting tool | - Pressure of the knife is 6 bar - Stroke of the knife is48mm50Hz - Size of the knife is0.5mm×3mm×2300mm - Oscillating speed is 3000t/minute | |

| Operating option | -modem (can do remote diagnosis and maintenance) -automatic programming software -computer console -absolute value control system -automatic angle adjustment -independent press roller -hanging control panel (optional) | |

| Max cutting speed | Depending on different materials, the max cutting speed is usually15m/minute. | |

Muye’s V6 foam cutter, a vertical CNC contour cutting machine, is great for cutting straight lines, curves, circles, other shapes and large foam blocks into smaller pieces. It is a powerful and useful piece of foam cutting equipment.

In the past, when cutting a shape that is anything but square, the pattern first had to be drawn onto the block before being manually cut on a traditional vertical cutting machine. Both speed and quality depended on the operator’s skill, and the cutting process was dangerous to the operator. The final finished product had a rough, uneven surface.

Our CNC vertical contour cutting machine solves those problems. Using this CNC foam cutter, the operator needs only to input the cutting pattern into the computer, place the foam block in the correct position, then hit the automatic button. The rest of the process is up to the machine.

Features

High Automation level

Easy to use