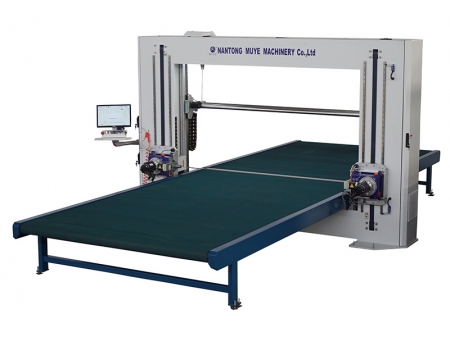

Foam Cutter (Horizontal and Vertical CNC Contour Cutting Machine, Model HV6)

Uses

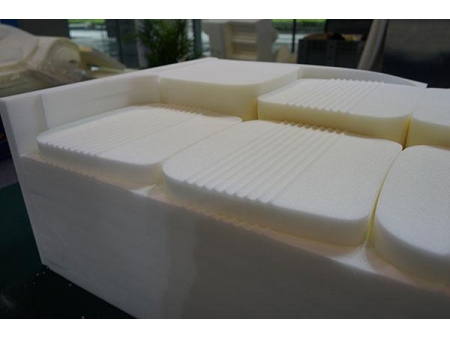

This particular version of CNC foam cutter can cleanly cut almost any geometric pattern wanted, and the pattern can then be used in a variety of industries.

Materials that can be cut

PU, PU soft foam, sticky foam, latex, rebond foam, Basotect, frame foam, PE

Shapes

Anything

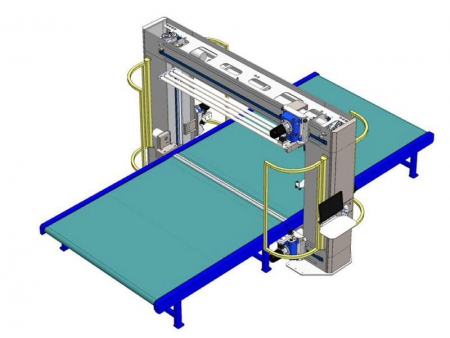

| HV6 Standard | Option | |

| Length of the foam block | 3000mm | 4500mm/5000mm |

| Height of the foam block | 1250mm | 1500mm |

| Width of the foam block | 2200mm | 2300mm |

| Work table | Lengthening work table | |

| AC power | 380V 3phase 4wire | |

| Total power | 5KW | |

| Max cutting speed | 10m/minute | |

| Cutting precision | ±0.5mm | |

| Cutting tool | -Pressure of the blade is 6 bar -Stroke of the blade is48mm50Hz -Blade size (horizontal): 2530mm×3mm×0.6mm -Blade size (vertical): 1570mm×3mm×0.6mm -Oscillating speed is 3000t/minute | |

| Operating option | Remote diagnosis and maintenance Automatic programming software Computer console Absolute value control Automatic angle adjustment Separate press roller Hanging control panel | |

| Max cutting speed | Depending on different materials, the max cutting speed of HV6 is15m/minute. | |

HV6 foam cutter is Muye’s foray into the world of contour cutting centers. This horizontal and vertical CNC contour cutting machine has impressed users with its high cutting speed and precision. When combined with user-friendly control, this CNC cutting equipment becomes a highly efficient and flexible tool for any contour cuts. In addition to making great horizontal and vertical cuts, it can also perform a complete cutting of nearly any outline, as its optional turntable greatly increases the range of its applications.

Features

1. The foam cutter is suitable for cutting foam in small batches, but can still cut in complex designs.

2. This is a new model, with a reasonable designed gearbox, internal mechanics that are fastened together more firmly, and an improved cooling performance.

3. A new electrical cabinet makes use of space within the worktable, which means it occupies less space, while still maintaining a high efficiency.

4. Our machine has a brand new transmission system, which improves the stability, synchronization, and cutting precision.

5. Its movable console makes it easy to observe and operate.

6. Each of our new contour cutting machines belong to the same series, and can all work in conjunction with each other. The automation level is higher (meaning they have automatic blade adjustment, automatic zero calibration, automatic searching of the processing range, and pre-judgments on oversteps), and production efficiency is also improved.