CNC Foam Cutting Machine, Model CNCHK-3

Request a Quote

(with Vertical Oscillating Blade)

Request a quote

Videos

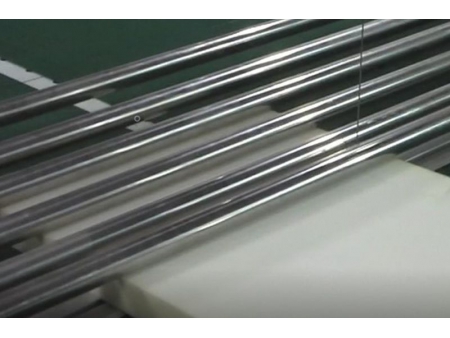

CNCHK-3 CNC foam cutting machine uses vertical blade for foam contour cutting with high speed and precision, which is a good alternative to foam die cutting machine. With cut-off and trimming unit, the CNC foam cutter is ideal for use in the production of automobile parts, upholstered furniture, and mattresses, as well as in the packaging and insulation industries. High cutting accuracy, dust-free cutting and maximized material efficiency are the main advantages of the foam processing machine.

Contour Cutting Samples

- Contour cut foam

- Contour cut foam

- Contour cut foam

Applications

- Foam fabrication

- Upholstered furniture

- Mattress

- Packaging

- Automotive

- Household

Materials

- PU foam

- High resilience foam

- Memory foam

- Latex foam

- Rebond foam

Technical Data

| Max. block size | 3000*2200*1300mm |

| Toothed blade size | 1630*3*0.6mm |

| Cutting speed | 0-6.3m/min |

| Accuracy | ±0.5mm |

| Press roller | Yes |

| Operation system | Windows 7 |

| Computer | Industry computer |

Features

- High cutting accuracy of ±0.5mm

- Simple operation with state-of-the art control technology

- Maximized material efficiency

- CNC contour blades with long service life

- The foam processing which is interrupted due to power outage will start from the breaking point after power on.

- Dust-free cutting: Foam is cleanly sliced, not abrasively cut, so there is no dust generated. A clean dust-free surface to the finished product is essential for mattresses, pillows and medical applications. This also helps keep a clean, safe workplace.

- ZWCAD and nesting function for automatic typesetting and easily created cutting path for automatic contour cutting

- High-precision monitoring system ensure fully synchronization of motors, to avoid blade broken.

Standard

- Servo protection device

- Blade breakage alarm and blade protection device (self-developed servo load detecting system, ensuring improved service life of the blade)

- Self-diagnosis system

- ZWCAD (available with commonly used keyboard shortcuts, automatic typesetting, one button for creating cutting path)

- Press roller

Options

- Worktable with extended length

- Extension table

- Nesting software