Automatic Flexo Printer Slotter Die Cutter Stacker

Corrugated cardboard converting machine combining feeding, printing, slotting, die-cutting and scrap removal

This automatic flexo printer slotter die cutter stacker is ideal for processing corrugated cardboard and carton products. It integrates feeding, printing, slotting, die-cutting, and scrap removal into one seamless operation. Designed to meet high standards with reliable functionality, this user-friendly machine allows for quick setup, modifications, execution, and memory functions, providing accurate data display throughout the process.

| Model | |||||

| Design speed (sheets/min) | 100 | 120 | |||

| Max. feeding size (mm) | 1400×2200 | 1600×2800 | 1200×2200 | 1200×2400 | 1200×2800 |

| Min. feeding size (mm) | 380×700 | 350×650 | |||

| Sheet size with skip feeding (mm) | 1650×2200 | 1650×2800 | 1500×2200 | 1500×2400 | 1500×2800 |

| Max. printing size (mm) | 1400×2200 | 1600×2600 | 1200×2000 | 1200×2200 | 1200×2600 |

| Printing precision (mm) | Double colors ±0.35 Three colors ±0.5 Four color ±0.75 | ||||

| Standard printing plate thickness (mm) | 7.2 | ||||

| Min. slotting distance (mm) | 290×60×290×60 | ||||

| Max. slotting depth (mm) | 240 | 300 | |||

| Printing roller axial adjustment (mm) | ±7 | ||||

| Die cutting cardboard layers | 3-5ply (slotting cardboard layers: 3/5/7ply) | ||||

-

Feeding Unit

Uses no-crush wheels with vacuum assistance to feed cardboard smoothly, preventing damage and ensuring consistent alignment. The adjustable airflow can be tailored to match the curvature of the cardboard, optimizing the feeding process

-

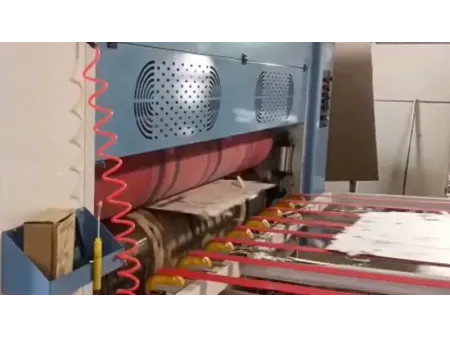

Printing Unit

Features high-precision, gapless rollers that have been polished, balanced, and chrome-plated. This ensures stable and smooth operation, delivering consistent print quality

-

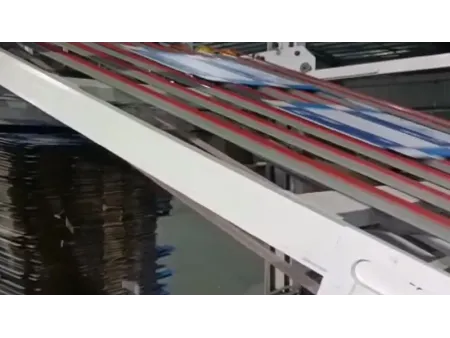

Slotting Unit

Equipped with sawtooth-shaped blades made from heat-treated and ground alloy steel. These durable blades are sharp and long-lasting, ensuring precise and efficient slotting