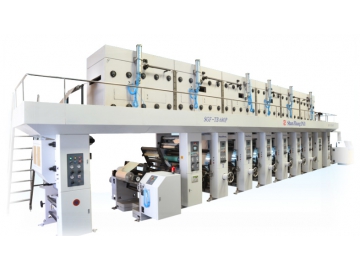

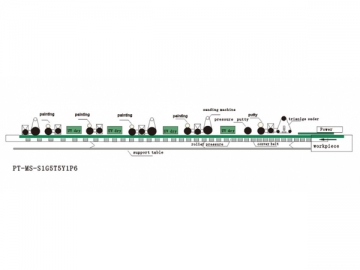

Edge Roll Coating Machine

Doorframe Edge Coating Machine / Doorframe Processing Machine / Edge Roll Coating Machine

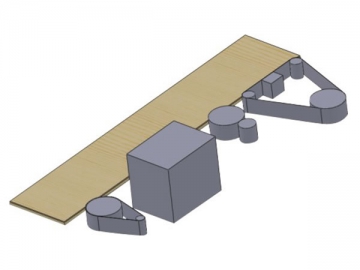

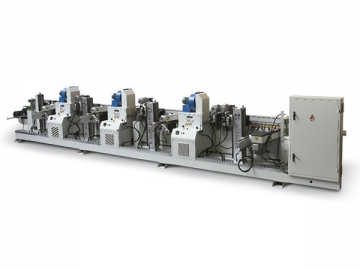

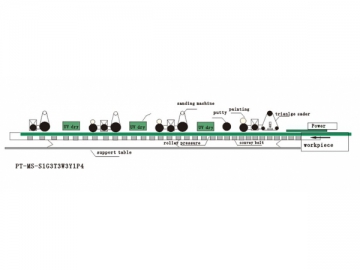

Machine Picture: (machines are made according to specific customer requirements)-

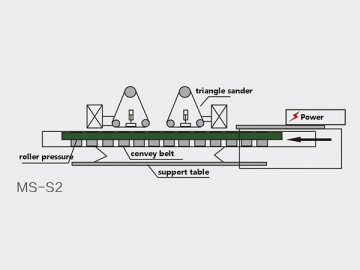

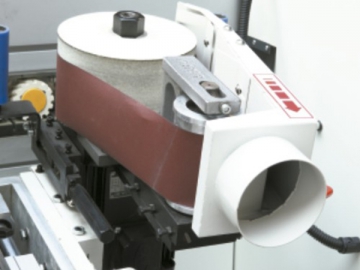

(S) Sanding of base material

(S) Sanding of base material -

(T) roller painting of putty and prime

(T) roller painting of putty and prime -

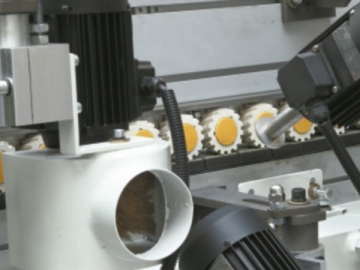

(G) UV curing

(G) UV curing -

(P) Dust removal and polishing

(P) Dust removal and polishing -

(W) Sanding of primer

(W) Sanding of primer

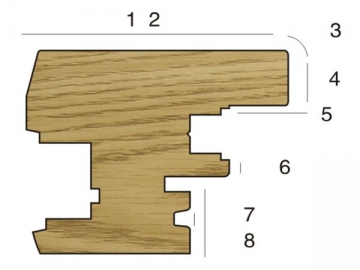

Applications

The edge roll coating machine for doorframes is used to sand and UV coat door leaves and door frames.

Features

The feeding speed is adjustable, with a maximum of 15 meters/minute, giving the doorframe processing machine its high production efficiency.

Coating types can go from a white body to a primer in a single usage cycle.

The sanding belt's speed and coating use a frequency control in order to meet different edge sanding and coating requirements for various material.

The pressure device utilizes a wheel press (though users can choose a belt press), and features transportation stability to ensure the workpiece does not undergo undue stress, as well as to ensure the surface of the workpiece is protected.

The edge roll coating machine also uses a chain conveyor whose speed can be adjusted. The doorframe processing machine also uses a cylindrical guide rail, a strong feeding power, and overall, the performance is stable and reliable.

The sanding head and coating roller are automatic in both the front and back of the doorframe edge coating machine.

Customers need to provide:

1. Information about the workpiece: product images, dimensions (minimum and maximum length, width and height), materials (MDF, wood, or other materials) and a sample

2. Any other specific requirements for customized machinery

After receiving the aforementioned information, we will choose the right doorframe edge roll coating machine for your needs.

Precautions for use:

Roll coat system, edge coating machine, UV edge coater