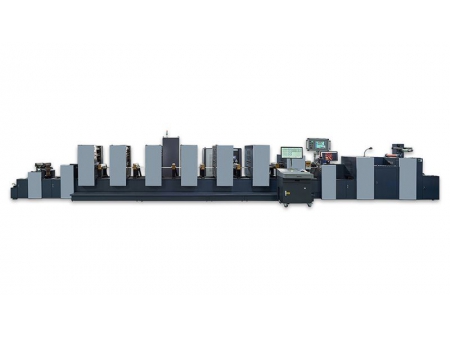

InlOffset Printing Press, DBJY-320/450

Label printing machine

Daba Machinery presents offset printing press that can achieve a ultra-large printing area of 300mm*350mm for labels. It offers a maximum printing speed of 180 meters per minute with 4- to 10-color printing options, ensuring stable and consistent color results. Optional units include varnishing, cold foil stamping, and die-cutting units, providing cost-saving benefits with easy operation and maintenance.

All printing substrates such as paper, metal sheets, cardboard, glass sheet and vinyl.

Label printing for color magazines, books, advertisement, name cards, and other commercial uses.

- The intermittent label printing machine is equipped with the latest servo control system to ensure stable and precise material gripping.

- Intermittent printing on PS plates meets the high-end label requirements, short or long, making it the best choice for printing high-quality labels at the lowest production cost.

- Printing roller replacement is unnecessary.

| Model | DBJY-320 | DBJY-450 |

| Maximum Substrate Width | 320mm | 320mm |

| Maximum Printing Width | 300mm | 300mm |

| Maximum Printing Length | 350mm | 350mm |

| Maximum Printing Speed | 50~180RPM | 50~150RPM |

| Maximum Unwinding Diameter | 700mm | 700mm |

| Maximum Rewinding Diameter | 600mm | 600mm |

| Printing Color | 4- to 10-color | 4- to 10-color |

| Power Supply | Three-phase, 380V | Three-phase, 380V |

| Total Power | 33.6KW (excluding UV curer) | 40KW (excluding UV curer) |

| Dimensions (L*W*H) | 10550* 1600 * 1800mm | 11150* 1600 * 1800mm |

| Net Weight | 9500KG | 11500KG |

- Unwinding Unit

- Linear Guide

Ensuring the paper is conveyed in a straight line.

- Heavy-duty Offset Printing Unit

We use high-quality heavy-duty offset printing units with an excellent ink path system that effectively prevents ink streaks and ghosting, significantly improving printing quality. The precision and clarity achieved in printing are beyond what letterpress printing machines are capable of.

- No-shaft Servo Motor System

Each printing unit operates with its independent servo motor. For example, a 6-color printing machine requires 15 servo motors to ensure accurate color matching during high-speed operation.

- Monitoring System

With the static image monitoring system, you can adjust the horizontal and vertical registration of the substrates on the main control panel while the machine still in operation. This effectively improves the quality and productivity of the printed products.

- Control Panel

A 12-inch touchscreen display is provided, with each printing unit equipped with its own independent touchscreen. The powerful human-machine interface allows for multi-angle detection and real-time alarm signals, making operations simpler and more efficient.

- Traction Unit

- Quality Control Unit

- Second-pass Registration Sensor

- Cold Foil Stamping Unit

- Rotary Die Cutting Station

- Flexographic UV Varnishing Unit

- Exhaust/Laminating Unit

- Screen Printing Unit