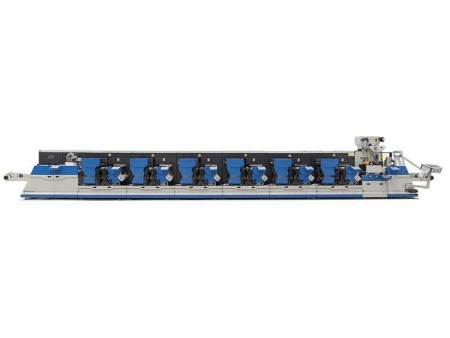

Modular Multi-function Rotary Printing Machine, DBJR-320

Request a Quote

Flexo & offset combination printing machine for label & narrow web

Our modular multifunctional rotary printing machine combines flexographic and offset printing in a flexible manner. It is suitable for various substrates with thickness ranging from 0.04mm to 0.35mm, including paper, film, metalized foil, and cardboard. This rotary printing machine can achieve 4 to 12-color printing, offering a wide range of printing effects to meet diverse printing needs.

Applications

- Label printing for flexible packaging of food,

- Label printing for bottles of liquor, medicine, drinks or perfume.

Applicable Materials

All substrates with thickness ranging from 0.04mm to 0.35mm, including paper, film, metalized foil, and cardboard.

Specifications

- Model: DBJR-320

- Printing Speed: 150m/min

- Printing Color: 4-12-color

- Repeat Length: 469.9-635mm

- Maximum Substrate Width: 420mm

- Minimum Substrate Width: 210mm (paper), 315mm (film)

- Maximum Printing Width: 410mm

- Substrate Thickness for Effective Printing: 0.04-0.35mm

- Maximum Unwinding Diameter: 1000mm/350Kg

- Maximum Rewinding Diameter: 1000mm/350Kg

- Maximum Unwinding/Rewinding Diameter for Cold Foil Stamping: 600mm/40Kg

- Offset Plate Thickness: 0.30mm

- Flexo Plate Thickness: 1.14mm

- Rubber Blanket Thickness: 1.95mm

- Double-sided Adhesive Thickness: 0.5mm

- Servo Motor Power: 16kW

- UV Curer Power: 7kW

- Power Supply: Three-phase, 380V±10%

- Voltage: 220V/50Hz

- Dimensions (L*W*H): 13m*2.22m*2.28m (5-color printing machine)

- Net Weight of Offset/Flexo Printing Unit: 2270kg

- Net Weight of Unwinder: 1400kg

- Net Weight of Die Cutting/Peeling Machine: 1350kg

- Net Weight of Rewinder: 920kg

Features

- The ink tray and fountain roller of the offset printing unit are controlled by a cooling thermostat to maintain stable ink viscosity.

- All the offset printing cylinders (plate cylinder, blanket cylinder, and impression cylinder), rubber rollers, and ink rollers are driven by independent servo motors, ensuring better stability.

- With the PMC printing management center, machine parameters can be adjusted anytime. Operators can easily store and retrieve printing projects, and set up the machine for the next project.

Details

- Flexible combination of offset and flexo printing

- Overprint sensor detects and identifies any overprint errors, and ensures overprint stability by recalibrating the print speed.

- Rotary die cutting

- Waste exhaust

- PMC printing management center

- Drying system effectively dries the ink in high-speed printing. Cooling water circulating system reduces material shrinkage during the UV curing process.

- Flexo printing unit