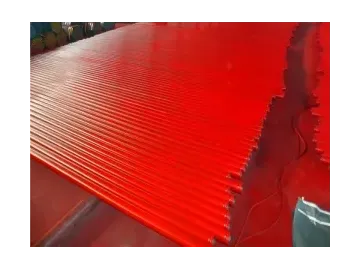

Painted ERW Steel Pipe

RuiTong Steel manufactures painted ERW steel pipes that meet the high standards of quality and environmental safety. Using innovative spray equipment and advanced painting techniques, which include precise control of spray distance, pressure, speed, and angle, we ensure our painted pipes offer exceptional thickness, gloss, smoothness, and adhesion. Our choice of high-quality, eco-friendly paints adheres to national and international standards, providing a finish that stands out in any engineering and usage environment.

Painted steel pipes offer several advantages, including enhanced rust resistance, reduced welding splatter, and lower overall maintenance costs. These benefits make them ideal for applications requiring both aesthetic appeal and long-term durability. Common uses include structural frameworks, fencing, firefighting system, and various industrial fabrications.

Standard

- ASTM A53

- ASTM A500

- API 5L

- ASTM A795

- IS065

- BS1387. BS1139

- GBT 3091 & GB/T13793

- GBT 3094

Applications

- Structural Pipe/ Structural Tubing

- Pipe Railing

- Scaffolding Pipe

- Fire Fighting Pipe

- Greenhouse Pipe

- Low Pressure Liquid Delivery Pipe

Size

- Outside Diameter:

Round tube: 21.3mm to 609.6mm

Square tube: 10×10mm to 200×200mm

Rectangular tube: 20×40mm to 80×120mm - Wall Thickness: 0.8mm to 17.5mm

- Paint Color: Black, red or other color (customizable)

- Length:

Regular length: 5.8m or 6m or 12m

Custom cut-to-length: 2m to 12m

- Plain End

- Beveled End

- Grooved End

- Threaded End

| DN | Designation of Thread | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | ||

| 15 | 1/2 | 21.40-21.00 | 0.843-0.827 | 1.80 | 0.071 |

| 20 | 3/4' | 26.90-26.40 | 1.059-1.039 | 2.00 | 0.079 |

| 25 | 1' | 33.80-33.20 | 1.331-1.307 | 2.00 | 0.079 |

| 32 | 1-1/4' | 4250-41.90 | 1673-1.650 | 2.00 | 0.079 |

| 40 | 1-1/2' | 48.40-47.80 | 1.906-1.882 | 2.3 | 0.091 |

| 50 | 2' | 60.20-59.60 | 2.370-2.346 | 2.30 | 0.091 |

| 65 | 2-1/2' | 76.00-7520 | 2.992-2.961 | 2.60 | 0.102 |

| 80 | 3' | 88.70-87.90 | 3.492-3.461 | 2.60 | 0.102 |

| 100 | 4' | 113.90-113.00 | 4.484-4.449 | 3.20 | 0.126 |

| DN | Designation of Thread | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | ||

| 15 | 1/2' | 21.40-21.00 | 0.843-0.827 | 2.00 | 0.079 |

| 20 | 3/4' | 26.90-26.40 | 1.059-1.039 | 2.30 | 0.091 |

| 25 | 1' | 33.80-33.20 | 1.331-1.307 | 2.60 | 0.102 |

| 32 | 1-1/4' | 4250-41.90 | 1.673-1.65 | 2.60 | 0.102 |

| 40 | 1-1/2' | 48.40-47.80 | 1.906-1.882 | 2.90 | 0.11 |

| 50 | 2' | 60.20-59.60 | 2.370-2.346 | 2.90 | 0.114 |

| 65 | 2-1/2' | 76.00-75.20 | 2.992-2.961 | 3.2 | 0.126 |

| 80 | 3' | 88.70-87.90 | 3.492-3.461 | 3.20 | 0.126 |

| 100 | 4' | 113.90=113.00 | 4.484-4.449 | 3.60 | 0.142 |

| DN | Designation of Thread | Outside Diameter | Wall Thickness | |||

| (mm) | (inch) | (mm) | (inch) | |||

| 15 | 1/2' | 21.70-21.10 | 0.854-0.831 | 2.6 | 0.102 | |

| 20 | 3/4' | 27.20-26.60 | 1.071-1.047 | 2.6 | 0.102 | |

| 25 | 1' | 34.20-33.40 | 1.346-1.315 | 3.2 | 0.126 | |

| 32 | 1-1/4' | 42.90-42.10 | 1.689-1.657 | 3.2 | 0.126 | |

| 40 | 1-1/2' | 48.80-48.00 | 1.921-1.890 | 3.2 | 0.126 | |

| 50 | 2' | 60.80-59.80 | 2.394-2.354 | 3.6 | 0.142 | |

| 65 | 2-1/2' | 76.60-75.40 | 3.016-2.969 | 3.6 | 0.142 | |

| 80 | 3' | 89.50-88.10 | 3.524-3.469 | 4 | 0.157 | |

| 100 | 4' | 114.90-113.30 | 4.524-4.461 | 4.5 | 0.177 | |

| 150 | 6' | 166.10-164.10 | 6.539-6.461 | 5 | 0.197 | |

| NPS | Outside Diameter | Wall Thickness | ||

| (mm) | (inch) | (mm) | (inch) | |

| 1/2' | 21.30 | 0.840 | 2.77 | 0.109 |

| 3/4' | 26.70 | 1.050 | 2.87 | 0.113 |

| 1' | 33.40 | 1.315 | 3.38 | 0.133 |

| 1-1/4' | 42.20 | 1.660 | 3.56 | 0.140 |

| 1-1/2' | 48.30 | 1.900 | 3.68 | 0.145 |

| 2' | 60.30 | 2.375 | 3.91 | 0.154 |

| 2-1/2' | 73.00 | 2.875 | 5.16 | 0.203 |

| 3' | 88.90 | 3.500 | 5.49 | 0.216 |

| 4' | 114.30 | 4.500 | 6.02 | 0.237 |

| 6' | 168.30 | 6.625 | 7.11 | 0.280 |

| 8' | 219.10 | 8.625 | 8.18 | 0.322 |

- Leveling

- Ends Cutting

- Slitting

- Recoiling

- Coil Ramp

- Uncoiling

- Leveling

- Ends Cutting

- Trimming & Welding

- Coil Accumulator

- Strip Ultrasonic Testing (UT)

- Forming

- High Frequency Welding

- Welding

- Deburring

- Seam Annealing

- Air/Water Cooling

- Sizing (Round Tube)

- Online Ultrasonic Testing (U.S. Test)

- Sizing (Square & Rectangular Tube)

- Straightening

- Flying Cut-off

- Flattening Test

- End Finishing

- Hydrostatic Test

- Appearance Inspection

- Offline Ultrasonic Testing (U.S. Test)

- Marking

- Oil Coating

- Packaging & Storage