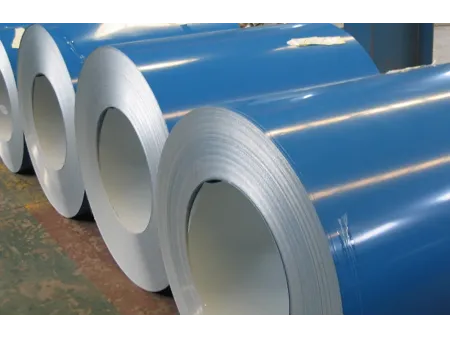

Pre-Painted Steel Sheet and Coil

Flat-Rolled Steel

- Thickness 0.18-1.00mm

- Width 900-1300mm

- Coil inner diameter Ø508/Ø610mm

- Coil weight generally, <5t, max. 10t

- Standard TDC51D Z, CGCC (JIS G3312), EN10169

- Coating structure two-coat two-bake (2/2), two-coat one-bake (2/1)

- Paint thickness max. 30µm (only one layer)

- Paint type PVDF (fluorocarbon), HDP (high weather resistance polyester)

- Production capacity 15 production lines, 5,000,000 tonnes of processed steel per year

- Minimum order quantity 20 tonnes

Worldwide delivery from the Philippines available upon request

Pre-painted steel coils use a galvanized steel base, enhanced with an organic coating that significantly boosts its corrosion resistance. This additional layer not only protects the steel from environmental damage but also increases its durability, making it suitable for a variety of demanding applications. Polyester is the most commonly used coating, offering a great balance between cost and performance. For more specific requirements, we provide fluorocarbon coatings, which excel in weather resistance, and high-durability polyester, perfect for long-term outdoor use or harsh conditions. Pre-painted steel is widely used in construction, home appliances, and transportation, combining functionality with aesthetic appeal.

- Our pre-painted steel production process offers flexibility to meet our customer needs. Depending on the application, we can apply single-coat single-bake, double-coat single-bake, or double-coat double-bake processes to achieve the desired finish and durability.

- Regarding the color options, we offer a wide range to suit various design and functional requirements. Popular choices include ocean blue, light gray, orange, ivory, brick red, and pearl white, among others. We also offer customized color matching based on international standards, ensuring every product meets the exact specifications of our clients.

| Pre-Painted Steel Sheet | Nominal thickness | 0.18-1.00mm | Nominal width | 800-1250mm | |

| Pre-Painted Steel Coil | Inner diameter | 508mm or 610mm | |||

| Standard weight <5 tonnes;customizable upon request | |||||

| Thickness | Complies with enterprise standards | ||||

| Tailored production is available to meet unique client needs | |||||

| Coating Type | Standard:polyester topcoat,epoxy primer,and back coat | ||||

| Customized coatings are available upon request | |||||

| Substrate | Standard:hot-dip galvanized steel | ||||

| Customized options available for special requirements | |||||

| Coating Structure | 2/1 | The single-layer back coating offers moderate corrosion resistance and adhesion,but its scratch resistance is relatively low. Suitable for sandwich panels. | |||

| 2/2 | The double-layer back coating provides better corrosion resistance,scratch resistance,and formability. It is commonly applied to single-layer profiled sheets but has weak adhesion,which makes it unsuitable for sandwich panels. | ||||

Notes:

a. Testing is carried out in accordance with relevant industry standards to ensure consistent quality and performance.

b. Over time, the mechanical properties of steel sheets and coils may degrade due to aging. This can lead to increased yield and tensile strength, reduced elongation after fracture, and diminished formability, sometimes resulting in stretch strain marks. To maintain optimal performance, it is recommended to use the materials as soon as possible after delivery.

- Construction

Pre-painted steel sheets and coils are a good choice for both outdoor and indoor construction projects. Outdoors, it’s commonly used in factory buildings, agricultural storage, prefabricated housing components, corrugated roofing, and rainwater systems such as gutters. It’s also ideal for balconies, kiosks, and roller shutter doors. Indoors, it’s frequently used in door frames, light steel structures, ceilings, and ventilation ducts, offering both durability and versatility. - Home Appliances

Pre-painted steel has a durability and sleek finish that make it perfect for manufacturing refrigerators, washing machines, air conditioners, microwaves, and even toasters, ensuring long-lasting performance. - Furniture

In the furniture industry, pre-painted steel is used for items such as radiators, lampshades, wardrobes, tables, beds, lockers, and bookshelves, offering a modern and durable solution for everyday use. - Transportation

It’s widely used in the automotive and railway industries, particularly for interior panels, partitions, and containers. Additionally, it’s used in ship compartment panels and barriers, providing excellent structural integrity. - Other Uses

Besides the industries mentioned above, pre-painted steel is a good choice for whiteboards, trash bins, advertising boards, clocks, control panels, weighing scales, and even photography equipment, combining function with aesthetics.

Maintaining the quality of pre-painted steel requires proper storage. Here are some practices to ensure the pre-painted steel remains in optimal condition:

- Keep the pre-painted steel in a dry, ventilated indoor space to prevent issues caused by moisture or temperature changes. Outdoor storage or areas with frequent condensation should be avoided.

- Store materials in a clean environment, free from exposure to corrosive agents that could compromise their integrity.

- Use a flat, sturdy surface with adequate load-bearing capacity to support the products. Avoid direct contact with the ground by placing coils on rubber mats, wooden supports, or racks. Ensure the locking buckles of horizontal coils face upward.

- To prevent damage, avoid stacking steel coils. If stacking sheets, limit the layers and place heavier bundles at the bottom.

- Over time, mechanical properties such as pencil hardness, T-bend values, and impact resistance may degrade. To maintain performance, it is recommended to process the material promptly.

- Ensure sufficient space for lifting equipment to safely move the products without risk of damage.

- Arrange storage areas strategically for easy access, reducing unnecessary handling and movement.

To ensure the quality of pre-painted steel during transportation requires careful handling and adherence to specific procedures. Below are some recommendations to keep in mind:

- Always transport products in their original packaging. Do not remove or modify the protective materials provided at the factory, as they are designed to safeguard the product during transit. To avoid surface damage, place rubber pads between lifting tools and the product. Whenever possible, use specialized lifting equipment for added safety.

- Prepare the vehicle properly before loading. Clean the truck bed thoroughly, and line it with rubber mats or similar protective materials. Ensure the sides of the vehicle are also padded to prevent any packaging from being dented or scratched.

- Vertically packaged steel coils must remain upright during transportation and unloading to prevent deformation and ensure product stability.

- Secure all items firmly to prevent movement or rolling during transit, which could cause damage or even accidents. Proper securing also minimizes the risk of unexpected impacts.

- When unloading steel sheets, avoid dragging them across surfaces. The sharp edges or burrs from cutting can scratch or damage the layers underneath. Always lift sheets carefully and handle them gently, ensuring they don’t come into contact with hard or abrasive surfaces.

What types of businesses use pre-painted steel products?

Pre-painted steel products are used by a wide range of customers, including:

- Industrial construction companies

- Home appliance manufacturers

- Automotive manufacturers

- Photovoltaic product manufacturers

- Wind and nuclear power component manufacturers

- Product distributors

Can pre-painted steel products provide weather resistance test reports?

Pre-painted steel products come with authoritative weather resistance test reports, including the following data:

- ISO 16474 UV Aging: ΔE≤2 after 3,000 hours.

- GB/T 10125 Salt Spray Test: No blistering after ≥1,000 hours.

Can architectural pre-painted steel products pass wind uplift tests?

Are pre-painted steel products for home appliances certified as food-contact safe?

How is the coating stability of cold chain warehouse panels in low-temperature environments?

What is anti-scratch packaging solution for piano lacquer panels during transportation?

A five-layer protective packaging is used to prevent scratches:

- Electrostatic PE film

- 3D honeycomb paper

- VCI anti-rust paper

- AB flute carton

- PLA corner protectors

This protective packaging, combined with a clean packaging process, ensures a scratch rate of ≤0.1%, significantly lower than the industry standard of 3-5%.