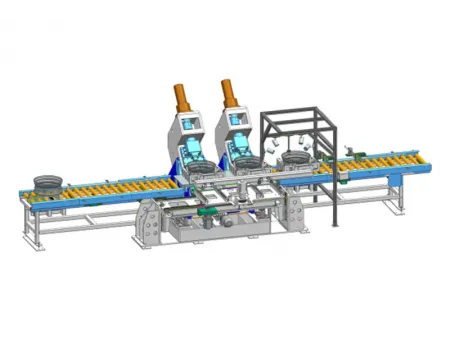

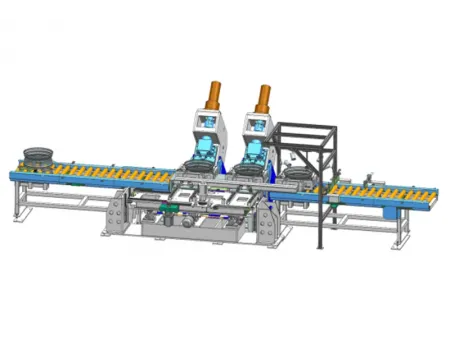

Valve Hole Punching Machine

Request a Quote

Wheel rim valve hole machine for accomplishing operations of flattening (coining), punching and deburring

The valve hole punching machine is used in wheel rim production line to perform flattening (coining), punching, and deburring operations on the rim, ensuring precise and clean valve hole formation on a pre-defined position. It is composed of four main sections: the flattening machine, punching machine, deburring machine, and an automated loading/unloading system, which work together to automate the valve hole punching process.

Component Functions

- The valve hole flattening (coining) machine creates a small flat surface on the rim where the valve hole will be positioned. This flat area improves the valve’s seal, preventing potential air leaks.

- The valve hole punching press drills a small, precise hole in the center of the flattened area, providing an exact fit for the valve stem.

- The valve hole deburring press removes any burrs or sharp edges around the valve hole, ensuring a smooth finish to prevent scratches or damage to the valve stem and its sealing components.

- The automatic loading and unloading system coordinate the operation of all three main components, enhancing efficiency of the valve hole punching process for wheel rims.

Process Flow Process Flow

- After expanding-sizing

- Valve hole punching

Specifications

| Model | |||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW | 64kW |

| Wheel rim thickness | ≤5mm | ≤8mm | ≤10mm |

| Wheel rim width | 5-8.25inch | 8.25-11.75inch | 11.75-16inch |

| Wheel rim diameter | 14-19.5inch | 19.5-24inch | 24-54inch |

| Max. capacity of flattening cylinder | 3400KN | 400KN | 460KN |

| Max. stroke of sliding block | 320mm | 400mm | 480mm |

| Nominal force of punching cylinder | 220KN | 250KN | 280KN |

| Max. stroke of punching cylinder | 28mm | 30mm | 32mm |

| Height between workbench and ground | 680mm | 750 mm | 920mm |

| Position repeatability | ±0.10mm | ±0.11mm | ±0.14mm |

Features

- The valve hole punching machine separates the traditional valve hole flattening, punching, and deburring processes into three dedicated units, solving common issues with standard machines, such as frequent punch breakage and difficult punch replacement.

- The automated loading and unloading system is driven by a high-power servo motor, ensuring consistent accuracy in positioning for each rim.

- Equipped with an independent hydraulic drive and electrical control system, the punch press utilizes PLC control, allowing for three operation modes: adjustment, manual, and semi-automatic.

- Includes over-travel and over-pressure protection, emergency stop, and filter clogging alerts for enhanced safety and reliability.

- Operating parameters such as working pressure, speed, and stroke range are fully adjustable to meet specific production requirements.

- Using image recognition technology, the system precisely identifies and locates the weld seam as the wheel rotates on the detection platform.

- The main frame can be adjusted for height, width, and tilt to accommodate rims of various sizes and specifications.