Air Leak Testing Machine

Request a Quote

Leak detector used in steel wheel production line to determine small leaks in the weld zone

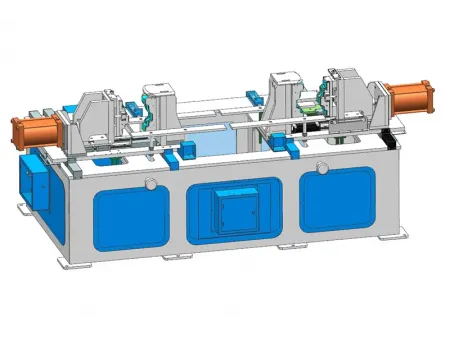

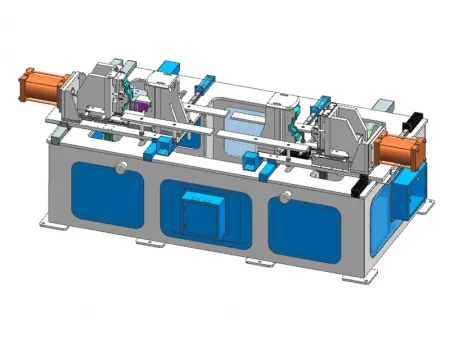

After the rim is fully formed, it passes through the air leak testing machine, which is specialized equipment in the steel wheel production line designed to detect any small holes and cracks in the weld area of wheel rims. This leak detector comprises three main sections: the mechanical unit, hydraulic power system, and electrical control system. These components are integrated via electrical connections to ensure synchronized operation, allowing for precise and reliable detection of even the smallest leaks in the weld area.

Process Flow Process Flow

Specifications

| Model | ||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW |

| Wheel rim width | 5-8.25inch | 8.25-11.75inch |

| Wheel rim diameter | 12-18inch | 16-25inch |

| Max. thickness of wheel rim | 4.6mm | 8mm |

| Voltage | 380V±10%, 3phase, 50HZ | 380V±10%, 3phase, 50HZ |

| Loading capacity of robotic manipulator | 205kg | 240kg |

| Machine weight | 1.5t | 2.2t |

| Compressed air | 0.4-0.6Mpa | 0.4-0.6Mpa |

Features

- The air leak testing machine offers both manual and automatic operation modes, with a balanced and ergonomic layout for ease of use.

- Constructed from thick welded steel plates, the frame is highly stable and durable.

- Powered by a pneumatic system, the mold operates efficiently and at high speeds.

- The dual-station setup enables faster air leak detection cycles, improving overall throughput.