Roll Forming Machine (Rim Roller)

Request a Quote

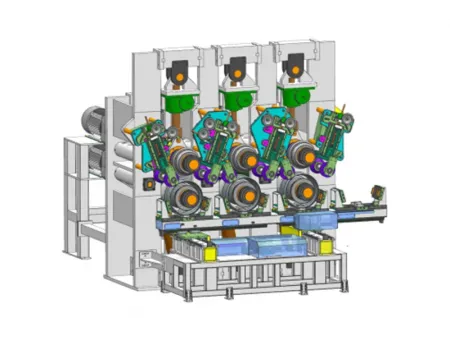

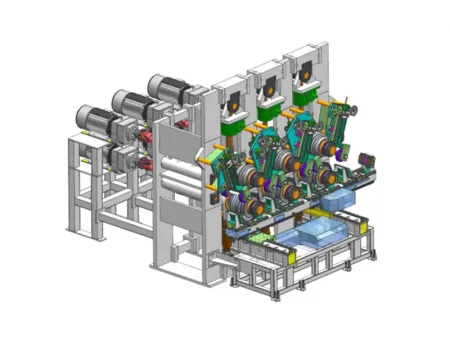

Wheel rim profiling machine used in steel wheel production line following the flaring operation

Following the flaring process, the rim band enters the first of typically three roll forming machines, where it is progressively shaped to its intended rim profile. The roll forming machine is used in steel wheel production to size wheel rims through a precise cold-forming process, that profiles both symmetrical and asymmetrical rim designs, accommodating diverse specifications and styles. Powered by a fully hydraulic system, the rim roller ensures smooth and efficient rim shaping, achieving the final contours required for high-quality wheel rims in an efficient wheel production line.

Process Flow Process Flow

- Initial flaring

- 1st roll forming

- 2nd roll forming

- 3rd roll forming

Specifications

| Model | |||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 460kW | 513kW | 544kW |

| Wheel rim thickness | ≤5mm | ≤8mm | ≤10mm |

| Wheel rim width | 200-400mm | 220-500mm | 260-800mm |

| Wheel rim diameter | 350-480mm | 420-580mm | 600-1000mm |

| Max. capacity of hydraulic cylinder | 230KN | 250KN | 280KN |

| Machine weight (with feeder) | 48T | 55T | 68T |

| Main spindle motor power | 70kW | 80kW | 90kW |

| Hydraulic cylinder stroke | 180mm | 200mm | 220mm |

| Main spindle diameter | Ø180mm | Ø220mm | Ø240mm |

| Distance between upper and lower spindle | 380-530mm | 395-550mm | 400-600mm |

| Adjustment range of upper and lower spindle | ±3mm | ±3mm | ±3mm |

| Tilting adjustment of upper and lower spindle | -0.34° to 0.17° | -0.34° to 0.17° | -0.34° to 0.17° |

| Lower spindle stroke | 165mm | 185mm | 205mm |

Features

- The main spindle is driven by a high-power servo motor, providing fast roll forming speeds with high precision.

- The three-stage roll forming machine features a compact, all-in-one design, enabling efficient wheel rim forming cycles.

- Hydraulic cylinders secure the clamps during automated loading and unloading, ensuring stability, high efficiency, and precise product output.

- High-power servo motors and rack-and-pinion gears drive forward, backward, left, and right movements, enabling fast and accurate material handling.

- Three cylindrical rim roller bearings on the front of the upper and lower spindles support high thrust loads.

- Both upper and lower spindles are equipped with a lubrication system, extending the machine's lifespan.

- The stroke of a side guide rail can be adjusted with a handwheel, allowing quick adaptation to various wheel rim types and specifications.