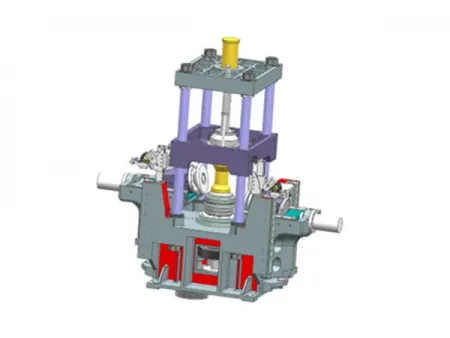

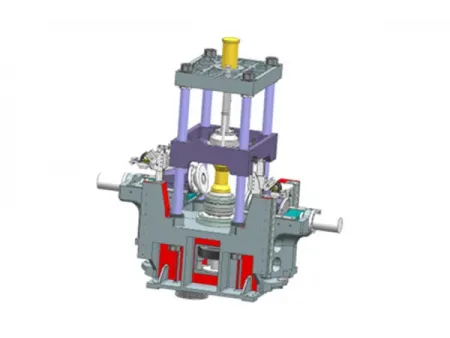

Wheel Disc Spinning Machine (Vertical Flow Forming Machine)

Request a Quote

Wheel forming machine used to make steel wheel discs

The wheel disc spinning machine is used to form steel wheel discs for various types of vehicles. This vertical flow forming machine is capable of spinning and shaping wheel discs for automotive applications, including tubeless and engineered steel wheels. By utilizing flow forming technology, it not only molds the disc into the desired shape but also enhances the structural strength of the finished product, ensuring durability and performance under demanding conditions.

Process Flow Process Flow

- Flow forming

- Flow forming

Specifications

| Model | ||

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ |

| Rated power | 46kW | 55kW |

| Wheel disc thickness | ≤5mm | ≤8mm |

| Wheel disc diameter | 10-19inch | 16-25inch |

| Wheel disc height | <140mm | <160mm |

| Circular steel blank diameter | 220-610mm | 350-782mm |

| Spinning time | ≤20-28s | ≤30-35s |

| Main spindle speed | 0-394r/min (stepless speed change) | 0-394r/min (stepless speed change) |

| Main spindle motor power | 180kW | 220kW |

| Upper cylinder clamping force | 500KN | 600KN |

| Upper cylinder stroke | 550mm | 600mm |

| Axial cylinder feed force | 540KN | 600KN |

| Axial cylinder stroke | 350mm | 400mm |

| Main cylinder feed force | 580KN | 630KN |

| Main cylinder stroke | 220mm (adjustable) | 220mm (adjustable) |

| Unloading cylinder pressure | 80KN | 100KN |

| Unloading cylinder stroke | 240mm | 300mm |

| Machine weight | 26T | 30T |

Features

- The wheel disc spinning machine offers enhanced wall-thinning capacity, surpassing similar spinning equipment on the market, which typically supports materials with a thickness reduction of 20mm or less.

- Capable of forming wheel discs in diameters ranging from 5.5 inches to 25 inches, both for tubed and tubeless designs, the vertical flow forming machine provides greater versatility compared to other models with limited diameter capacities.

- Designed to handle high-strength steel with a minimum tensile strength of 440 MPa, whereas conventional flow forming equipment is often limited to materials with a tensile strength of 380 MPa or lower.

- The arc and pressure angle of the forming wheel on the disc spinning machine are precisely designed and adjustable to produce a smooth, orderly surface finish on the formed product, surpassing the rougher finishes typical of comparable spinning equipment.

- Utilizing servo profiling, the flow former ensures easy, reliable contour adjustments for precise forming of disc profiles.

- An optional fully automated loading and unloading system enables seamless transfer of blanks from entry to completion without manual handling, unlike many disc spinning machines that require manual intervention.

- The main spindle diameter on the rim spinning machine is increased from 220mm to 260mm, with larger bearings and heavy-duty thrust ball bearings to support greater load capacity. Driven by an efficient permanent magnet synchronous motor, the spindle provides constant torque and stepless speed adjustment, accommodating disc sizes across various diameters.

- The spindle support in the spinning chamber is reinforced from 140mm to 150mm, with customized NSK bearings designed to handle high-load spinning for strong steel plates and long tubular bodies.

- Reinforced with heavy-duty thrust ball bearings, the upper spindle maintains stability in both pressing and spinning operations, ensuring consistent quality and performance in disc production.