Explosion Proof Refrigerated Air Dryer - EXTR Series

Designed for hazardous environments where explosion protection and corrosion resistance are critical, these refrigerated dryers integrate advanced safety features, efficient moisture removal, and eco-friendly refrigerants to ensure safe and reliable operation in demanding industrial applications.

- Degree of protection: Ex d IIC T4 Gb

- Ambient temperature: 0~42℃

- Compressed air inlet temperature: 15~65℃

- Compressed air pressure: 0.7MPa, Max.1.6MPa (or customizable)

- Pressure drop: ≤0.025MPa (at 0.7MPa inlet pressure)

- Pressure dew point: 3℃ (35℃ inlet temperature, 25℃ ambient temperature)

| Model | Max. air flow rate (m³/min) | Power supply | Input power (kW) | Air pipe connection | Evaporator type | Cooling method | Refrigerant | Total weight (kg) | Dimensions (L×W×H) |

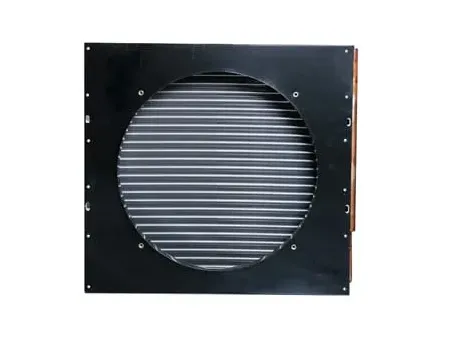

| 1.2 | 220V/50Hz | 0.4 | RC3/4" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R134a | 51 | 1080×660×750 | |

| 2.4 | 220V/50Hz | 0.57 | RC3/4" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R134a | 63 | 1080×660×750 | |

| 3.6 | 220V/50Hz | 0.86 | RC1" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R410A | 75 | 1210×660×750 | |

| 6.5 | 220V/50Hz | 1.52 | RC1-1/2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R410A | 94 | 1300×760×915 | |

| 8.5 | 220V/50Hz | 1.77 | RC2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R410A | 110 | 1460×960×1000 | |

| 10.5 | 220V/50Hz | 2.12 | RC2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R410A | 125 | 1460×960×1000 | |

| 13 | 220V/50Hz | 2.62 | RC2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R410A | 131 | 1600×1100×1000 | |

| 17 | 380V/50Hz | 4.35 | RC2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 270 | 1700×1000×1100 | |

| 23 | 380V/50Hz | 5.7 | RC2-1/2" | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 310 | 1800×1100×1160 | |

| 27 | 380V/50Hz | 6.55 | DN80 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 520 | 1815×1150×1230 | |

| 33 | 380V/50Hz | 7.4 | DN80 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 630 | 2025×1425×1480 | |

| 42 | 380V/50Hz | 10.85 | DN100 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 825 | 2175×1575×1640 | |

| 55 | 380V/50Hz | 12.8 | DN100 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 1020 | 2230×1630×1760 | |

| 65 | 380V/50Hz | 14.3 | DN125 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 1170 | 2580×1950×1743 | |

| 85 | 380V/50Hz | 16.62 | DN125 | Aluminum plate heat exchanger | Air-cooled finned-tube condenser | R407C | 1380 | 2655×2000×1743 | |

| Technical data available on request | |||||||||

- Display Interface: LED dew point temperature display, LED alarm code display, LED compressor current display, operating status indication

- Anti-Freezing Protection: Constant pressure expansion valve; Automatic temperature control/antifreeze solenoid valve

- Temperature Control: Automatic control of condensing temperature and dew point temperature

- High Voltage Protection: Temperature sensor & pressure sensitive intelligent protection

- Low Voltage Protection: Temperature sensor & pressure sensitive intelligent protection

- Remote Control: Optional configuration of remote connection dry contact, RS485 expansion interface (please let us know in advance if you need)

- Explosion-proof and corrosion-resistant design

Features either aluminum alloy or stainless steel three-in-one plate heat exchangers, providing robust explosion protection along with enhanced corrosion resistance for long-term reliability.

- Certified explosion protection

Fully compliant with Ex d IIC T4 Gb explosion-proof standards.

Incorporates a fully sealed explosion-proof electrical enclosure, with all electrical connections utilizing explosion-proof flexible conduits to ensure maximum safety in hazardous environments. - Intelligent control system

Equipped with multi-point temperature and pressure monitoring, real-time dew point display, and automatic recording of cumulative operating hours.

Integrated self-diagnostic functions with alarm codes and automatic protection protocols to ensure safe and stable operation. - Environmentally friendly

Uses eco-friendly refrigerants that comply with the Montreal Protocol, ensuring zero ozone depletion potential and suitability for global environmental regulations.

- Stable and adaptive performance

Standardized with a constant-pressure expansion valve that automatically adjusts refrigerant flow.

Optimized for both high-temperature operating conditions and low-temperature energy-saving modes, ensuring stable performance across a wide range of environments.