Boiler Pipe

For low to medium pressure boilers, Yunahua has an array of 4-30mm thick seamless steel pipes ranging in diameter from Φ76-Φ273mm. With an annual production capacity of 300,000 tons of steel pipes, we can deliver customer orders quickly and efficiently.

Each one of our steel tubes is made of quality carbon steel through a process known as hot rolling. We can build our hot rolled seamless steel pipes in a variety of standards, including DIN, JID, ASME and EN.

Not only do our carbon steel pipes have excellent chemical and physical properties, but they are put through hydrostatic tests, flanged, flattened, and expanded at both ends to check if the strength, elasticity, and pressure resistance meet industry standards. Cold rolled steel pipes go through heat treatments before delivery.

Standards

GB3087-2008, BS3059

Uses

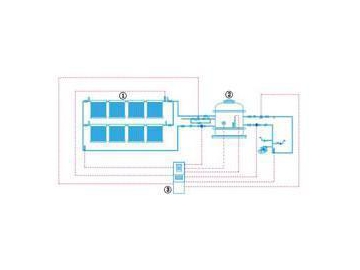

This series of steel seamless pipes are primarily used in low to medium pressure boilers, including locomotive boilers, general purpose industrial boilers, and domestic boilers. The seamless pipe can handle a maximum steam pressure of 6MPa, serve as a flue pipe and steam generating tube, and carry superheated steam and boiling water in the boiler system. It is also widely seen in urban plumbing.

| Standards | Steel Grades |

| GB3087 | 10 , 20 |

| GB5310 | 20G, 20MnG, 25MnG, 15CrMoG, 12Cr1MoVG, 12Cr2MoG, 12Cr2MoWVNbB |

| DIN17175 | ST35.8, ST45.8, 15Mo3, 13CrMo44, 10CrMo910 |

| ASME SA-106 | SA-106B, SA-106C |

| ASME SA-210M | SA-210A1, SA-210C |

| ASME SA-213M | T11, T12, T22, T23, T91 |

| ASME SA-335M | P5, P9, P11, P12, P22, P23, P91, P92 |

| ASME SA-192M | SA-192 |

| ASME SA-333 | SA333 Grade I, SA333 Grade VI |

| JIS G 3461 | STB340, STB410, STB510 |

| JIS G 3462 | STBA 12, STBA 13, STBA 20, STBA 23, STBA 24, STBA 26 |

| EN10216-1 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| EN10216-2 | P195GH, P235GH, P265GH, 16Mo3, 13CrMo4-5, 10CrMo9-10 |

| EN10028-2 | P235GH, P265GH, P355GH, 16Mo3, WB36 |

| Outer Diameter | Wall Thickness mm | ||||||||||||||||

| inch | mm | 2 | 2.6 | 3.6 | 4.5 | 5.5 | 7.1 | 9.5 | 12.5 | 13 | 14-16 | 17-19 | 20-25 | 31-60 | 61-70 | 81-90 | 91-120 |

| 0.84 | 21.3 | ||||||||||||||||

| 1.05 | 26.7 | ||||||||||||||||

| 1.315 | 33.4 | ||||||||||||||||

| 1.66 | 42.2 | ||||||||||||||||

| 1.9 | 48.3 | ||||||||||||||||

| 2.375 | 60.3 | ||||||||||||||||

| 2.875 | 73 | ||||||||||||||||

| 3.5 | 88.9 | ||||||||||||||||

| 4 | 101.6 | ||||||||||||||||

| 4.5 | 114.3 | ||||||||||||||||

| 5.563 | 141.3 | ||||||||||||||||

| 6.625 | 168.3 | ||||||||||||||||

| 8.625 | 219.1 | ||||||||||||||||

| 10.75 | 273 | ||||||||||||||||

| 12.75 | 323.9 | ||||||||||||||||

| 14 | 355.6 | ||||||||||||||||

| 16 | 406.4 | ||||||||||||||||

| 18 | 457 | ||||||||||||||||

| 20 | 508 | ||||||||||||||||

| 22 | 559 | ||||||||||||||||

| 24 | 610 | ||||||||||||||||

| 26 | 660.4 | ||||||||||||||||

| 28 | 711.2 | ||||||||||||||||

| 30 | 762 | ||||||||||||||||

| 32 | 813 | ||||||||||||||||

| 34 | 864 | ||||||||||||||||

| 36 | 914 | ||||||||||||||||

| 38 | 965 | ||||||||||||||||