Gypsum Board Production Line

Our line of gypsum board production line offers annual production between 3 and 60 million square meters. It is mainly used for paper-faced gypsum board manufacturing. We can offer custom designed plasterboard production lines according to users’ requirements.

Construction

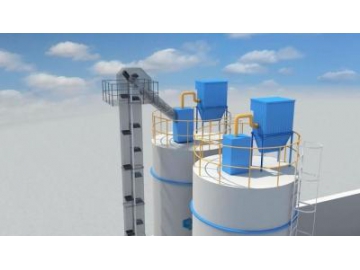

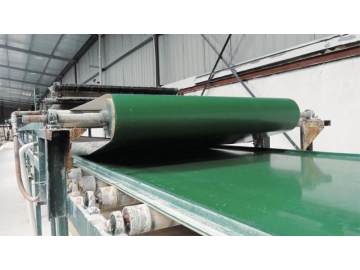

The gypsum board production line is typically made up of the dosing system, board forming equipment, belt over roller conveyor, cutting machine, dryer, and the packaging equipment.

It includes a PLC control system which allows the production line to realize continuous automated operation.

As one of the largest gypsum board manufacturing equipment manufacturer, we provide our clients with a complete range of services, including engineering technology support, equipment design, on-site equipment installation, and contract management.

Main Technical Data of the Gypsum Board Production Line| Annual Output (m 2) | 3,000,000 | 6,000,000 | 8,000,000 | 10,000,000 | 15,000,000 | 20,000,000 | 30,000,000 |

| Belt Over Roller Conveyor (m/min) | Vmax=6 | Vmax=12 | Vmax=13 | Vmax=20 | Vmax=32 | Vmax=43 | Vmax=62 |

| Dryer (m/min) | Vmax=0.6 | Vmax=1.2 | Vmax=1.5 | Vmax=1.7 | Vmax=2.1 | Vmax=2.1 | Vmax=2.36 |

| Total Power (Kw) | 363.97 | 384.37 | 283.44 | 490 | 550 | 550 | 600 |

Project Cases

We have designed and manufactured over 60 gypsum board production lines for our clients in different countries around the world, including Thailand, Indonesia, Vietnam, the USA, Italy, Columbia, and Mexico. Also we have successfully established cooperation with renowned plasterboard manufacturers such as Knauf and USG Boral.

| Time | Customer | Country |

| 2014 | ASK | Egypt |

| 2014 | KNAUF | Vietnam |

| 2013 | KNAUF | Thailand |

| 2012 | USG-BORAL | Vietnam |

| 2011 | USG-BORAL | Indonesia |

| 2008 | TECNOLOGIA EN CUBRIMIENTO, S.A | Columbia |

| 2008 | GESSI DEL LAGO D’LSEO SPA | Italy |

| 2009 | GYPSOPANEL INDUSTRIES, S.A.DE C.V. | Mexico |