Thermocouple

Theory and Construction

Thermocouple consists of two wires, each made of different metal, welded together at one end. When the welded point (measuring junction) is heated, a thermoelectromotive force is produced that is proportional to the temperature difference between the welded point and the other end (reference junction). Therefore, by measuring this thermoelectromotive force either with the reference junction temperature kept constant or by using an automatic compensation circuit, the temperature of measuring junction can be measured.

The thermoelectromotive force of a thermocouple is independent of the diameter or length of the wire used and it depends only on the type of the wire used.

Type of Thermocouple

| Material symbol | Leg | Main material | Leg dia. | JIS C 1602 | ANSI | ||

| JIS | ANSI | Max. Operating temp. In normal application (℃) | Max. Operating temp. In overheated application (℃) | Max. Operating temp. (℃) | |||

| B | Platinum 70% rhodium 30% | 0.5 | 0.5 | 1500 | 1700 | 1700 | |

| - | Platinum 94% rhodium 6% | 0.5 | 0.5 | ||||

| R | Platinum 87% rhodium 13% | 0.5 | 0.5 | 1400 | 1600 | 1480 | |

| - | high purity platinum | 0.5 | 0.5 | ||||

| S | Platinum90% rhodium 10% | 0.5 | 0.5 | ||||

| - | high purity platinum | 0.5 | 0.5 | ||||

| K | Nickel 90% chromium 10% Nickel 95% Manganese 2% Aluminum 2% | 3.2 | 3.2 | 1000 | 1200 | 1260 | |

| 2.3 | 1.6 | 900 | 1100 | 1090 | |||

| 1.6 | 0.8 | 850 | 1050 | 980 | |||

| 1 | 0.5 | 750 | 950 | 870 | |||

| 0.65 | 0.32 | 650 | 850 | 870 | |||

| E | - | Nickel 90% chromium 10% Copper 55% nickel 45 % | 3.2 | 3.2 | 700 | 800 | 870 |

| 2.3 | 1.6 | 600 | 750 | 650 | |||

| 1.6 | 0.8 | 550 | 650 | 540 | |||

| 1 | 0.5 | 500 | 550 | 430 | |||

| 0.65 | 0.32 | 450 | 550 | 430 | |||

| J | - | High purity iron Copper 55% nickel 45 % | 3.2 | 3.2 | 600 | 750 | 760 |

| 2.3 | 1.6 | 550 | 750 | 590 | |||

| 1.6 | 0.8 | 500 | 650 | 480 | |||

| 1 | 0.5 | 450 | 650 | 370 | |||

| 0.65 | 0.32 | 400 | 500 | 370 | |||

| T | - | High purity copper Copper 55% nickel 45 % | 1.6 | 1.6 | 300 | 350 | 370 |

| 1 | 0.8 | 250 | 300 | 260 | |||

| 0.65 | 0.5 | 200 | 250 | 200 | |||

| 0.32 | 0.32 | 200 | 250 | 200 | |||

| In addition to the above, special thermocouples, such as W-W26% Re, Cu-CoAu etc., are available as well. | |||||||

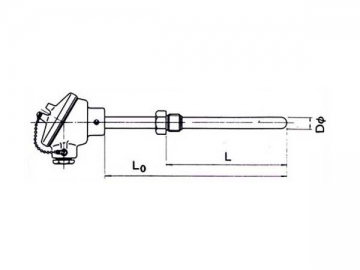

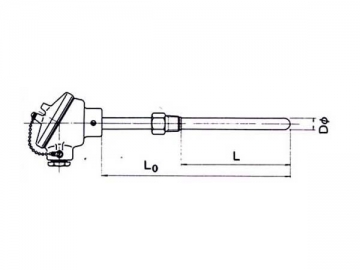

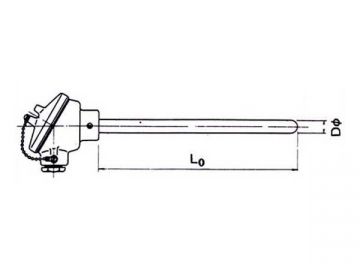

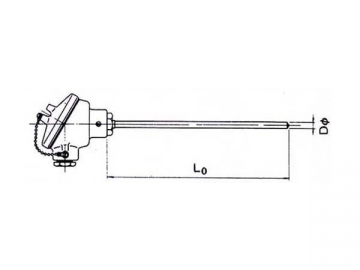

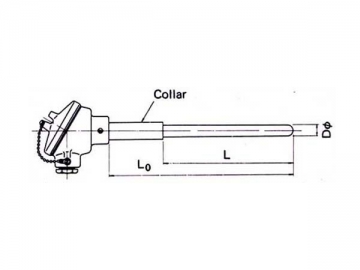

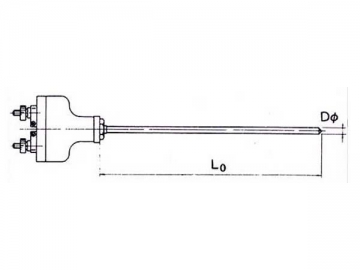

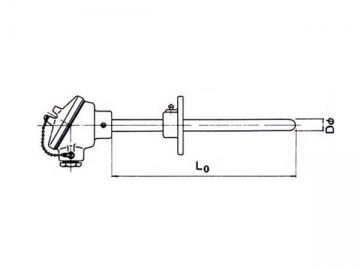

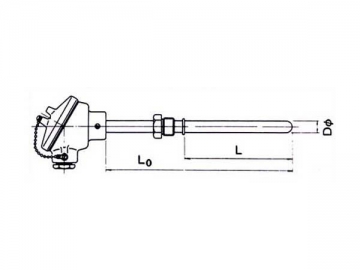

| Metal tube type | PT screw type |

| PF screw type | Gland type |

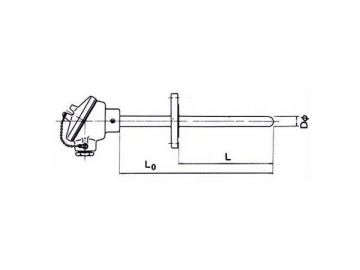

| Fixed flange type | Sliding flange type |

| Non-metal tube insertion type | |

In addition to the standard types listed above, double tube type, L-shaped type, explosion-proof type, and various other types of temperature sensors are available as required. | |

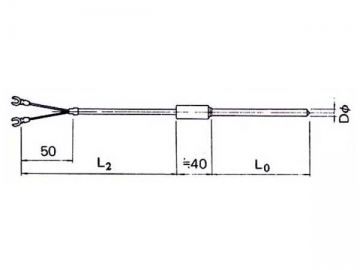

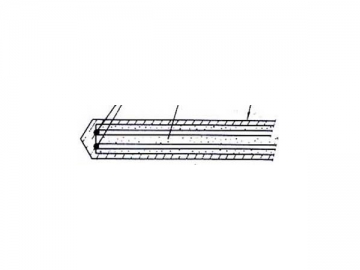

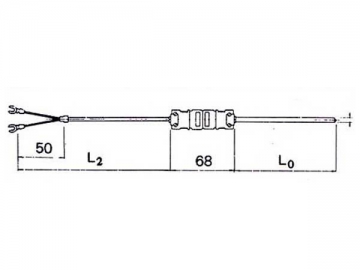

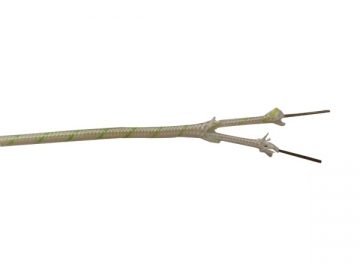

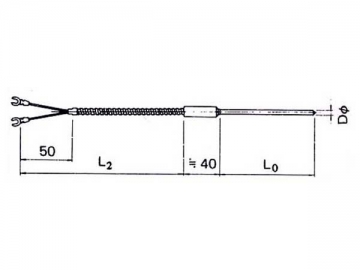

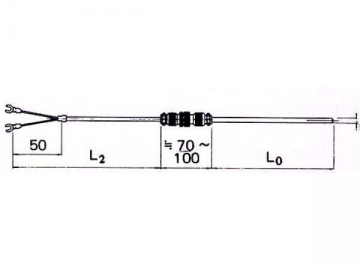

Sheath Thermocouples

The thermocouple is sealed in high temperature resistant metal tube. The space between the thermocouple and the metal tube is tightly packed with high-density insulation. Special features of the sheath thermocouple are its high flexibility (it can be bent freely into curves with a radius of twice the sheath OD or more); also its quick response speed, explosion-proof construction and outstanding resistance to vibration as well as many other advantages.

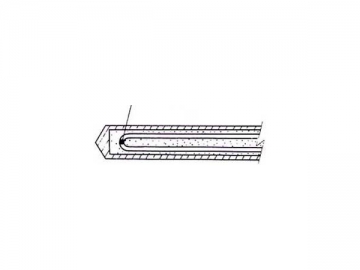

Standard Type of Hot Junctions

| Grounded | Un-grounded | Exposed | ||

| Measuring junction | Magnesia | Sheath | Measuring junction | Measuring junction |

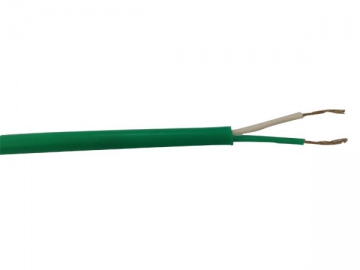

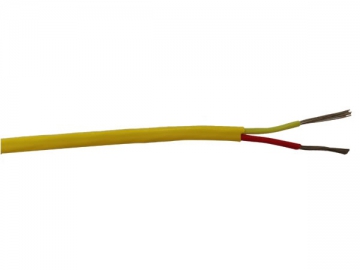

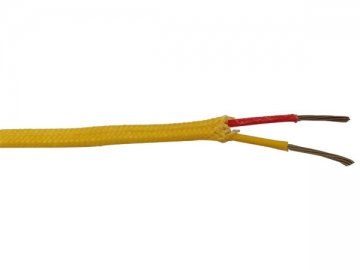

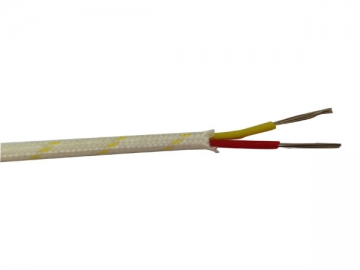

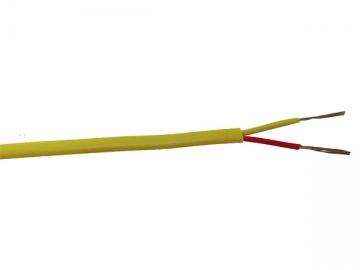

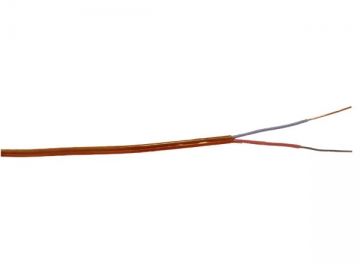

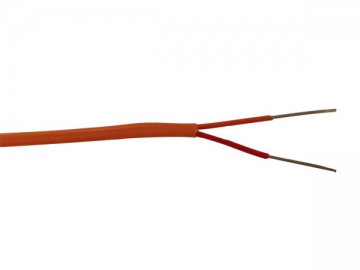

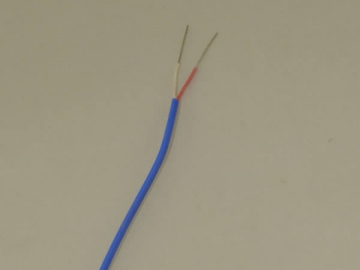

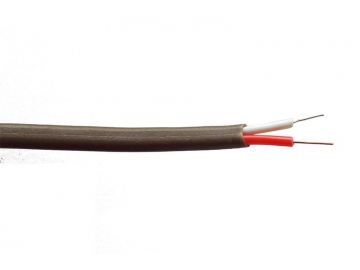

Thermocouple Wire Insulation Identification

| Insulation Code | Insulation | Appearance of Thermocouple Wire | Temperature Range, Insulation | Abrasion Resistance | Flexibility | Water Submersion | |

| Overall | Conductors | ||||||

| PVC | Polyviny Chloride (PVC) | Polyviny Chloride (PVC) | -40 to 105°C -40 to 221°F | Good | Excellent | Good | |

| FEP | Teflon or Neoflon | Teflon or Neoflon | -200 to 200°C -338 to 392°F | Excellent | Good | Excellent | |

| SIL | Sillicon Rubber | Sillicon Rubber | -200 to 200°C -338 to 392°F | Fair | Excellent | Excellent | |

| PFA | PFA Teflon or Neoflon | PFA Teflon or Neoflon | -200 to 200°C -338 to 393°F | Excellent | Good | Excellent | |

| KPT | Kapton | Kapton | -200 to 200°C -338 to 394°F | Excellent | Good | Good | |

| PFA/FG | Glass Braid | PFA Teflon or Neoflon | -73 to 260°C -100 to 500°F | Good | Good | Excellent | |

| FG | Glass Braid | Glass Braid | -73 to 482°C -100 to 900°F | Poor | Good | Poor | |

| HH | High Temp Glass Braid | High Temp Glass Braid | -73 to 704°C -100 to 1300°F | Poor | Good | Poor | |

| CF | Ceramic Fiber | Ceramic Fiber | -73 to 1204°C -100 to 2200°F | Poor | Good | Poor | |

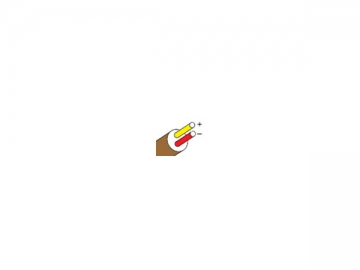

| ANSI Code | ANSI MC 96.1 Color Coding | Alloy Combination | Maximum T/C Grande temp. range | EMF(mv) Over Max. temp. range | IEC 584-3 Color Coding | IEC Code | ||

| Thermocouple grade | Extension grade | Lead | - Lead | |||||

| K |  |  | NICKEL- CHROMIUM Ni-Cr | NICKEL- ALUMINUM Ni-Al | -270 ~ 1372℃ -454 ~ 2501℉ | -6.458 ~ 54.886 |  | K |

| J |  |  | IRON Fe (magnetic) | CONSTANTAN COOPER-NICKEL Cu-Ni | -210 ~ 1200℃ -346 ~ 2193℉ | -8.095 ~ 69.553 |  | J |

| T |  |  | COPPER Cu | CONSTANTAN COOPER-NICKEL Cu-Ni | -270 ~ 400℃ -454 ~ 752℉ | -6.258 ~ 20.872 |  | T |

| E |  |  | NICKEL- CHROMIUM Ni-Cr | CONSTANTAN COOPER-NICKEL Cu-Ni | -270 ~ 1000℃ -454 ~ 1832℉ | -9.835 ~ 76.373 |  | E |

| N |  |  | NICROSIL Ni-Cr-Si | NISIL Ni-Si-Mg | -270 ~ 1300℃ -450 ~ 2372℉ | -4.345 ~ 47.513 |  | N |

| S | NONE ESTABLISHED |  | PLATINUM-10% RHODIUM Pt-10%Rh | PLATINUM Pt | -50 ~ 1768℃ -58 ~ 3214℉ | -0.236 ~ 18.693 |  | S |

| R | NONE ESTABLISHED |  | PLATINUM-13% RHODIUM Pt-13%Rh | PLATINUM Pt | -50 ~ 1768℃ -58 ~ 3214℉ | -0.226 ~ 21.101 |  | R |

| B | NONE ESTABLISHED |  | PLATINUM-30% RHODIUM Pt-30%Rh | PLATINUM-6% RHODIUM Pt-6%Rh | 0 ~ 1820℃ 32 ~ 3308℉ | 0 ~ 13.820 |  | B |

| Electromotive Characteristics of Thermocouple Unit: mV | |||||||

| Temp. (℃) | B | R | S | K | E | J | T |

| Pt70·Rh30 Pr94 ·Rh6 | Pt87 ·Rh13 Pt | Pt90 ·Rh10 Pt | Chromel Alumel | Chromel Constantan | Iron Constantan | Copper Constantan | |

| -200 | - | - | - | -5.891 | -8.824 | -7.890 | -5.603 |

| -100 | - | - | - | -3.553 | -5.237 | -4.632 | -3.378 |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 100 | 0.033 | 0.647 | 0.645 | 4.095 | 6.317 | 5.268 | 4.277 |

| 200 | 0.178 | 1.468 | 1.440 | 8.137 | 13.419 | 10.777 | 9.286 |

| 300 | 0.431 | 2.400 | 2.323 | 12.207 | 21.033 | 16.325 | 14.860 |

| 400 | 0.786 | 3.407 | 3.260 | 16.395 | 28.943 | 21.846 | 20.869 |

| 500 | 1.241 | 4.471 | 4.234 | 20.640 | 36.999 | 27.368 | |

| 600 | 1.791 | 5.582 | 5.237 | 24.902 | 45.085 | 33.0969 | |

| 700 | 2.430 | 6.741 | 6.274 | 29.128 | 53.110 | 39.130 | |

| 800 | 3.154 | 7.949 | 7.345 | 33.277 | 61.022 | 45.498 | |

| 900 | 3.957 | 9.203 | 8.448 | 37.325 | 68.783 | 51.875 | |

| 1000 | 4.833 | 10.503 | 9.585 | 41.269 | 76.358 | 57.942 | |

| 1100 | 5.777 | 11.846 | 10.754 | 45.108 | |||

| 1200 | 6.783 | 13.224 | 11.947 | 48.828 | |||

| 1300 | 7.845 | 14.624 | 13.155 | 52.398 | |||

| 1400 | 8.952 | 16.035 | 14.368 | ||||

| 1500 | 10.094 | 17.445 | 15.576 | ||||

| 1600 | 11.257 | 18.842 | 16.771 | ||||

| 1700 | 13.585 | 20.215 | 17.942 | ||||

| 1800 | 13.585 | ||||||

International express for sample or small orders;

Air transportation and sea transportation for big orders.