Precision Seamless Steel Tube and Pipe

Our precision seamless steel pipe is able to withstand high pressure, eliminate leakage, resist deformation when cold bending, and also can prevent crack when flattening. Further, it features high accuracy and smooth finish. The precision seamless tube is mainly applied for manufacturing pneumatic or hydraulic devices such as air cylinders and oil cylinders. The seamless steel pipe used on hydraulic rods is consumable. Therefore, we usually recommend our customers to stock up certain quantity of steel pipe when purchasing.

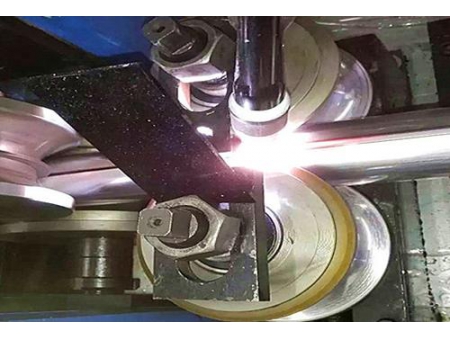

The production of precision seamless steel tube is demanding. Some unprofessional manufacturers often fail to determine the correct hardness of steel pipe during annealing process. They usually get excessive high hardness, which will make the steel pipe become brittle, thus further leading to fracture. With over ten years of rich experience, we are able to perfectly avoid such problem. Additionally, we will provide 24-hour support to help you solve problems thanks to our powerful after-sales team.

Analyzed by a third party inspection organization, our precision seamless steel tube and pipe constitute many chemical components such as C, Si, Mn, S, P and Cr.

Chemical Composition| Steel Type | Chemical Composition (%) | |||||

| ASTM | C | Si | Mn | S | P | Cr |

| 1010 | 0.07-0.13 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | |

| 1020 | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | |

| 1035 | 0.32-0.39 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | |

| 1045 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | |

| 5140 | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | 0.08-1.10 |