Hot Bent Glass

Color: clear, ultra clear, bronze, grey, and etc.

Thickness: 4-25 mm

Size: Min. size 300*300 mm up to maximum size 3660*11000 mm

Standard: GB15763.2 (China), EN12150-1 (EU), ASTM C1048 (US) and AS/NZS2208 (Australia)

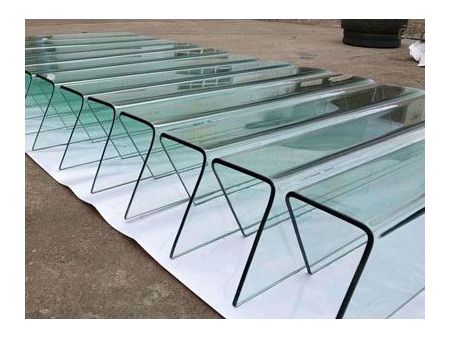

Hot Bent Glassis a sophisticated type of curved glass that has become an essential element in modern architectural design. This high-quality material is created through a complex process involving heating and softening flat glass, shaping it in a mold, and then annealing it to form a curved surface. Typically, this process occurs in electric furnaces with continuous heat-bending furnaces boasting 5-6 chambers and 11-13 stations, enabling the production of one finished piece every few dozen minutes. Conversely, intermittent heat-bending furnaces have only one chamber and complete all the heating, forming, and annealing processes within it, taking several hours up to one or two days to produce a small batch of large heat-bent glass.

There are three primary types of Hot Bent Glassbased on shape: single bend, hot bend, and composite bend. Single bend architectural glass is comparatively easier to heat-bend, but many manufacturers struggle to align the curved edges around 150 mm away from the straight edge with the mold, sometimes exceeding standard requirements and resulting in installation difficulties. To address these issues, CHINASTAR GLASS adopts a reasonable heating arrangement of the heat-bending furnace, allowing for local heating, and the direction of product placement must match the direction of the heating wire.

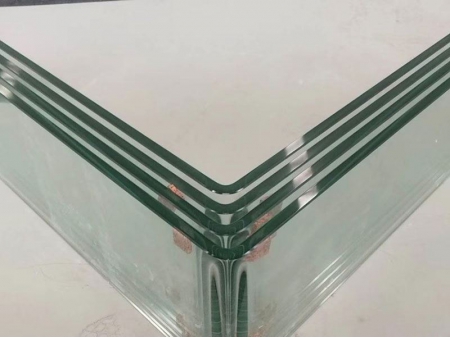

Hot Bent Glass is often used for aquarium glass and counter glass. However, the biggest technical challenge for Hot Bent Glassis the appearance of mold marks at the straight edge bends and corners. Therefore, specialized heat-bending furnaces and precise mold-making techniques are required to create curved glass such as spherical glass, arched hallways, and glass basins, which demand high technical expertise in heat-bending operations.

- Aesthetics: Curved shapes of hot bent glass have no connecting joints in the middle, resulting in visually appealing lines and achieving an overall harmonious effect.

- Specificity: Hot bent glass can be made into various shapes based on different customer requirements.

- Hot bent glass is created by heating and softening high-quality glass and shaping it in a mold, then annealing it for durability. It has visually appealing curves with smooth lines and a beautiful style. And hot bent glass is more flexible and diverse in its applications compared to flat glass.

- Hot bent glass can be used for fish tanks, dining tables, balconies, phone counters, cosmetic counters, hot-bent TV cabinets, doors, windows, ceilings, curtain walls, and more.

- Various types of composite hot bent glass products can be produced, such as insulated glass and laminated glass. These products can be customized according to customer requirements, making them a versatile option for any project.