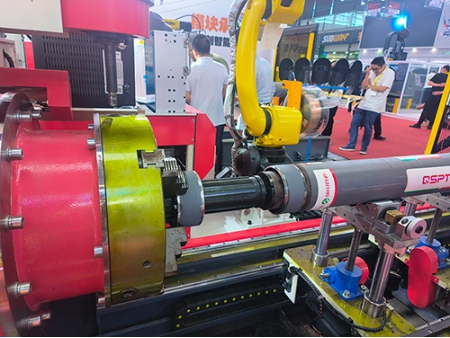

Pipe Fit-Up & Welding System for Pipe Spool Prefabrication

Pipe fabrication equipment for aligning, fitting and welding of pipe segments, flanges, and fittings

The intelligent pipe fit-up & welding system for pipe spool prefabrication is designed to streamline fit-up and welding operations in the pipeline fabrication process. Its main function is to precisely align the ends or multiple components of pipelines, enabling automated welding that ensures exceptional precision and efficiency in pipeline connections. This advanced welding system is compatible with a variety of materials, including carbon steel, stainless steel, and alloy steel.

The intelligent pipe fit-up & welding system is widely used in various industrial sectors, such as petroleum, chemical, and natural gas industries. It is an invaluable tool for modern pipeline construction and maintenance.

The pipe fit-up and welding system consists of:

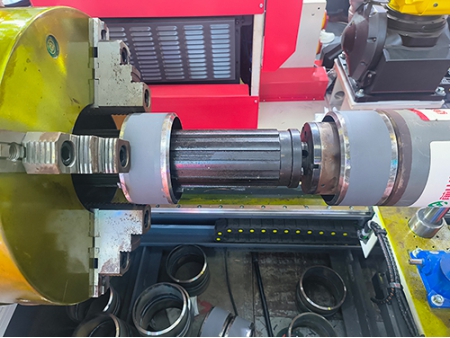

- Positioner drive system (specially designed modular chuck, can be equipped with dual systems)

- Megmeet welding power supply

- Centered support trolley system

- Flux delivery and recovery system

- Welding rail trolley system

- Welding PLC control system

- FANUC welding robot

- Visual robot control system

- Binocular laser vision system

- Steel structure box-type base

Module-type pipe prefabrication intelligent production line

Applicable Pipe SpoolOne dimensional pipe spool with fittings on one or both sides (supported by modular carrier)

Applicable ProcessTruss manipulator intelligent lifting, special modular chuck clamping, vision robot intelligent SAW filling, submerged arc weld (SAW)

Applicable RangeDN50-300 (diameter) × 3-20mm (wall thickness)