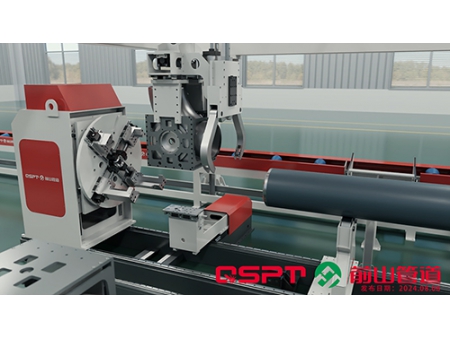

Pipe Fit-Up & Root Pass Welding System for Pipe Spool Prefabrication

Pipe fabrication equipment for aligning, fitting and welding of pipe segments, flanges, and fittings

The pipe fit-up and root pass welding system plays a crucial role in pipe prefabrication and installation. Employing advanced sensors and laser vision technology, the system provides real-time monitoring of pipe diameter, wall thickness, and length. This ensures precise fit-up, resulting in superior welding performance and minimized tolerance.

The pipe fit-up and root pass welding system consists of:

- Head frame clamping drive system

- Chuck tensioning and centering system (machining chuck)

- Binocular laser vision system

- EWM hot wire TIG power supply

- Tungsten electrode automatic replacement system

- Workpiece support trolley system

- PLC control system

- Tailstock clamping drive system

- Visual robot control system

- Welding rail trolley system

- Steel structure box-type base

- Fanuc welding robot

Pallet carrier type intelligent pipe prefabricated production line

Applicable Pipe SpoolOne-dimensional pipe spool with pipe fittings on one or both sides (elbows with special module)

Applicable ProcessTruss manipulator intelligent hoisting, machining chuck clamping, vision robot intelligent pairing, intelligent TIG spot welding, intelligent TIG bottoming

Applicable RangeDN50-300 (diameter) × 3-20mm (wall thickness)

- High accuracy and stability. The system features a centering clamping mechanism and roller frame to precisely center, clamp, and convey pipe spools. This ensures stability and accuracy during the fit-up process.

- High efficiency. An efficient welding power supply and torch are included, supporting TIG, MIG, SAW, and other welding methods to accommodate various pipe materials and specifications.

- High quality. Automatic wire feeding and weld tracking technologies guarantee welding process continuity and stability, resulting in improved weld quality.