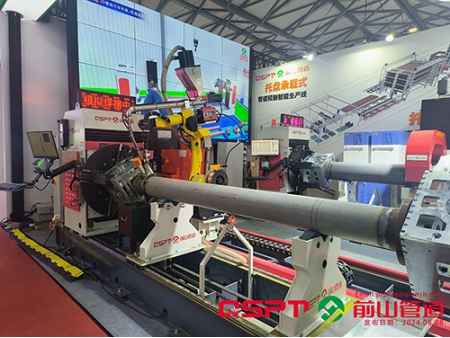

Submerged Arc Welding System for Pipe Spool Prefabrication

Pipe welding system for joining pipes and fittings

The intelligent submerged arc welding system is used for enhancing and optimizing the welding process in pipeline prefabrication. It is designed for high-precision submerged arc welding (SAW) operations, improving efficiency, consistency, and welding quality.

By integrating advanced sensors and artificial intelligence (AI) technology, the welding system enables real-time monitoring of the welding process. It can dynamically adjust parameters based on actual conditions, ensuring stable, high-quality, and safe welding. This intelligent system reduces manual intervention, enhances productivity, and ensures the reliability of welded joints in pipeline prefabrication.

The welding system consists of:

- Positioner drive system (specialized modular chuck)

- Megmeet welding power supply

- Centered support trolley system

- Flux delivery and recovery system

- Welding rail trolley system

- Welding PLC control system

- FANUC welding robot

- Visual robot control system

- Binocular laser vision system

- Steel structure box-type base

The submerged arc welding system is suitable to pair with module-type pipe prefabrication intelligent production line.

Applicable Pipe SpoolOne dimensional pipe spool with fittings on one or both sides (supported by modular carrier)

Applicable ProcessTruss manipulator intelligent lifting, special modular chuck clamping, vision robot intelligent SAW filling, submerged arc weld (SAW)

Applicable RangeDN50-300 (diameter) × 3-20mm (wall thickness)